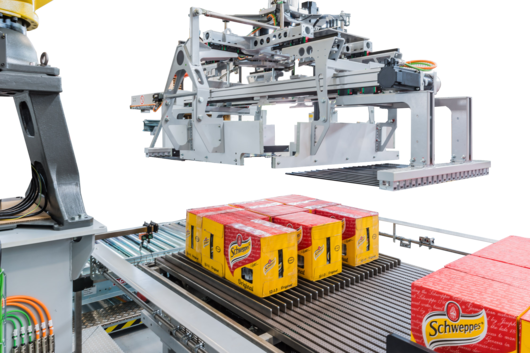

trusted worldwide for flexible, reliable solutions

We specialize in secondary packaging machines, depalletizing and palletizing systems, stretch wrappers, and integrated internal logistics — all built to perform.

Case studies

Logistics and end-of-line for Caviro

A complete end product handling system, spanning palletising to preparation of the shipping bays, all perfectly in synch with the automatic warehouse located onsite.

Case studies

OCME and Robopac innovations for Mahou

Ocme and Robopac are working together to provide the best end-of-line solutions in the beverage sector to a key Spanish customer, Mahou.