Operational efficiency is crucial at every stage of production, especially when it comes to meeting growing market demands. Nowhere is this more evident than at the end-of-line phase, where products must be packaged securely for transport and distribution. For key decision-makers looking to maintain speed and consistency in their manufacturing operations, automation isn’t just an option — it’s a necessity.

Automatic carton packing machines have emerged as a key innovation for this process. Through end-of-line packaging automation, operators can maximize packaging efficiency, streamline operations and improve packaging consistency. With more buyers demanding product variety and volume, carton packing automation has become an essential component of modern manufacturing strategies.

What Are Automatic Carton Packing Machines?

Automatic carton packing machines are advanced case packing systems used in end-of-line packaging automation. After packing products into cartons or cases, they are ready for shipment, distribution or the next step of the supply chain. These machines safely handle, arrange and pack items according to predefined configurations, eliminating manual steps and increasing output.

The core purpose of carton packing automation is simple: speed up production, improve packaging quality, minimize labor costs and ensure that every unit shipped maintains the highest standards of consistency and protection.

Whether standalone or integrated into a fully automated production line, carton packing systems are adaptable for products ranging from bottles and cans to personal care and industrial goods. When used correctly, carton packing machines help manufacturers stay competitive by streamlining packaging for future product handling.

How Does Carton Packing Automation Work?

Though the process can vary depending on the machine and your existing operations, carton packing automation typically follows a structured, efficient process designed to ensure fast and accurate product packaging:

- Product Infeed: Products arrive at the machine via a conveyor system. The carton packing automation system should already have the predefined configurations.

- Grouping and Collating: The machine groups products into the correct arrangement, which can vary based on quantity, size and orientation.

- Carton Formation: A blank or preformed carton is erected or selected, depending on the machine type.

- Product Insertion: Using mechanical or robotic arms, the grouped products are precisely inserted into the carton.

- Carton Sealing: The carton is securely sealed with adhesives, tape or glue. This ensures the package is ready for transportation.

- Outfeed: The sealed carton is transferred to the next stages in the production line: palletizing, warehousing or shipping.

What Are the Different Types of Automatic Carton Packing Machines?

Choosing the right automatic carton packing machine can improve packaging efficiency. However, the best machine for your operations depends on factors such as product type, packaging format, space availability and production volume.

Wrap Around Case Packers

Key Features:

- Precision-formed cartons for enhanced strength

- Optimized material usage with minimal waste

- High-speed, continuous operation capability

Wrap around case packers build cartons by wrapping a flat sheet of corrugated material tightly around grouped products and sealing it in place. Unlike manual case erecting and packing, this method forms a precise, close-fitting carton that enhances stability during handling and transportation.

The wrap-around technology of these machines reduces material waste, improves case integrity and supports higher speeds on automated lines, making them ideal for operations prioritizing efficiency and load security.

Pick and Place Packers

Key Features:

- Robotic precision for delicate product handling

- Flexible adaptation to different product geometries

- Compact design for easy integration into existing lines

Pick and place packers use robotic arms or mechanical systems to lift individual products directly from a conveyor and position them carefully into preformed cartons. These systems are highly adaptable and can manage products of varying shapes, weights and fragility with exceptional accuracy. They are particularly suited for delicate or premium items that require gentle handling to prevent damage during packaging.

Side Load Case Packers

Key Features:

- High-speed horizontal packing

- Accommodates a wide range of case sizes and formats

- Smooth, consistent handling of heavy or rigid products

Side load case packers insert grouped products horizontally into open cartons before sealing them. This method is ideal for products that need to maintain a specific orientation or arrangement within the case, such as items with liquids.

Side loaders deliver high throughput rates and can manage various packing patterns. This makes side load case packing machines a reliable choice for manufacturers dealing with uniform, tray-packed or multipack goods.

Top Load Case Packers

Key Features:

- Gentle product placement for fragile goods

- Versatile carton configuration options

- Easy changeover for different product lines

Top load case packers load products vertically into open cartons from above using pick heads or robotic mechanisms. This vertical placement provides a controlled, gentle packing process, ideal for lightweight, fragile or irregularly shaped products.

Top loaders can accommodate a wide array of carton dimensions and are often chosen for retail-ready packaging applications requiring high presentation standards.

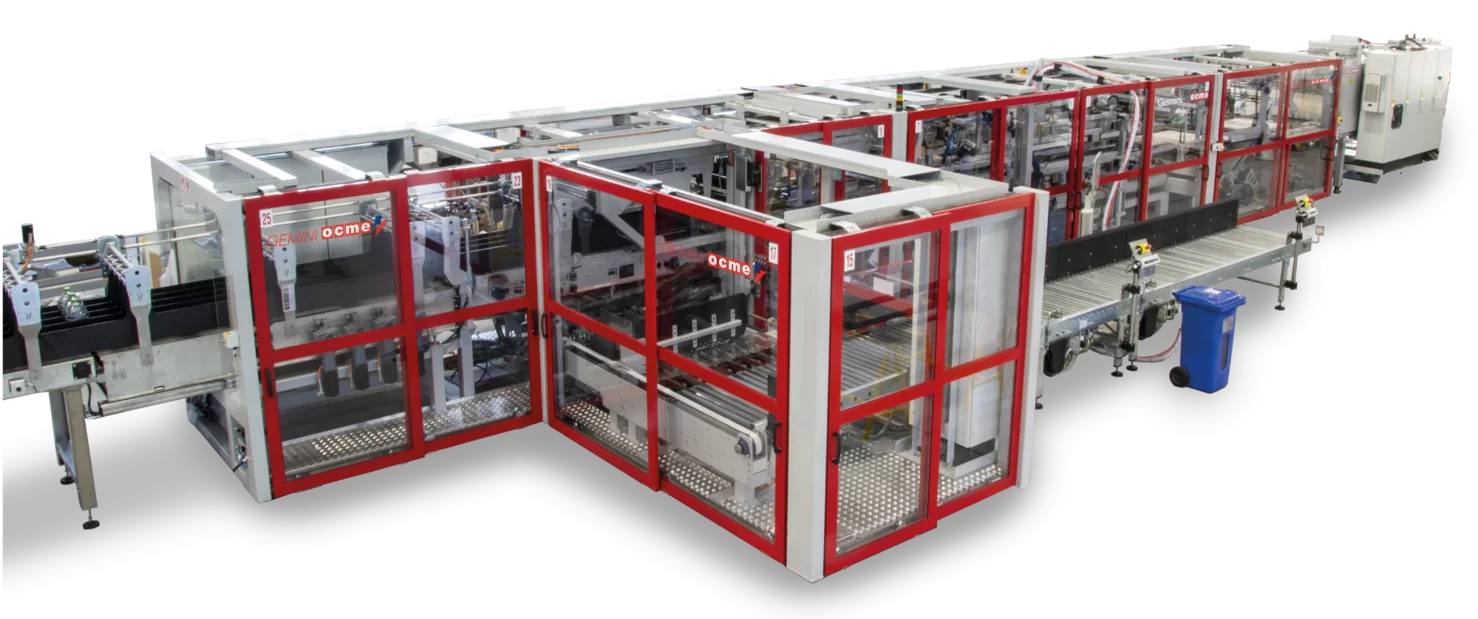

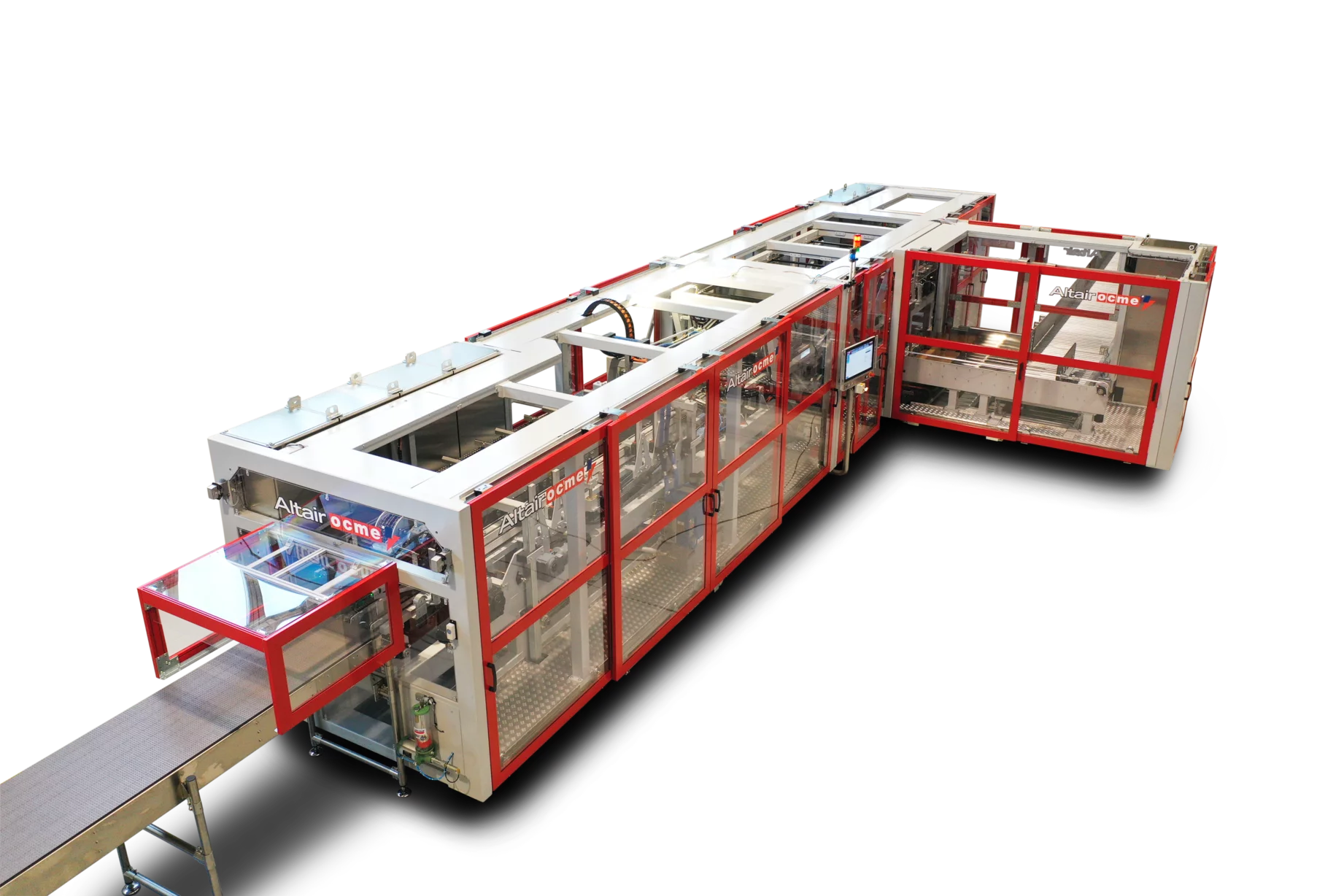

Combination Packers

Key Features:

- Multi-format packaging within one system

- Rapid changeovers with minimal manual adjustment

- Integration-ready for full automation and modular upgrades

Combination packers are multi-functional systems capable of performing several packaging operations. Instead of investing in multiple machines, you can invest in versatile combination packers that provide wrap-around case packing, tray packing and stretch wrapping within a single integrated machine.

This flexibility allows manufacturers to switch between different products or packaging styles with minimal downtime. Combination packers are ideal for operations that produce diverse product portfolios or seasonal variations. This is also the best choice for facilities that want to maximize operational versatility.

What Are the Benefits of Carton Packing Machines?

Implementing an automatic carton packing system helps improve packaging efficiency and delivers measurable advantages that significantly enhance overall business performance. Some key benefits of carton packing machines include.

Increasing Throughput

End-of-line packaging automation operates continuously at high speeds, drastically increasing packaging output. By removing manual bottlenecks, facilities can scale production, fulfill larger orders faster and respond more agilely to market demand. This sustained increase in throughput drives higher profitability and strengthens market competitiveness.

For example, manual packing often limits operational efficiency. However, by implementing a high-speed wrap-around case packer, operations can fulfill high-volume retail orders during peak season without additional labor or overtime.

Reducing Manual Labor

Replacing manual packing tasks with automation reduces the reliance on labor-intensive processes. This can lower labor costs and minimize the risk of human error. It also enhances workplace safety by eliminating repetitive strain injuries and heavy lifting traditionally associated with manual packaging.

Enhancing Consistency

Automation ensures that every product is packed with precision, regardless of shifts, worker fatigue or production volume fluctuations. You can trust that every package is consistent, which can promote brand integrity and reduce product damage. Depending on the type of product you produce, you may also need consistency to comply with stringent quality standards demanded by modern consumers and retailers.

Optimizing Material Usage

Modern carton packing machines are designed to minimize material waste. Advanced technology allows computers to precisely calculate the amount of carton or film needed for each package.

Aside from reducing operational costs, this advantage also reduces material waste. When you improve packaging efficiency, you support corporate sustainability goals by lowering the environmental footprint associated with packaging operations. Over time, this can significantly reduce the volume of packaging waste and contribute to a company’s broader initiative to reduce landfill contributions.

Facilitating Scalability

As businesses grow, production demands evolve. Automatic carton packing machines allow manufacturers to easily scale operations by adding new modules, increasing speeds or adjusting for different package sizes without the need for completely new equipment investments. This flexibility ensures long-term return on investment and adaptability to changing market trends.

Why Robopac USA?

Robopac USA is at the forefront of packaging innovation. We help manufacturers in various industries by delivering end-of-line solutions that combine cutting-edge technology with unmatched reliability.

Our automatic carton packing machines are engineered to meet the dynamic needs of modern manufacturing. Here are some reasons why key decision-makers in manufacturing centers partner with Robopac USA:

Tailored Solutions: Every business has unique requirements. We work collaboratively with our customers to design solutions that optimize performance based on their production goals.

Superior Engineering: Our machines are built for longevity and minimal maintenance.

Comprehensive Support: From consultation and installation to training, spare parts and lifecycle maintenance, we are committed to supporting your operations at every stage.

Proven Track Record: Leading global brands across beverage, food, personal care and industrial sectors trust Robopac USA for their packaging automation needs.

With Robopac USA, you have a trusted partner dedicated to your success. We provide more than just the machines to streamline your process – we deliver lasting value and a competitive advantage.

Streamline Your Operations With Robopac USA

Efficiency is a top priority in any manufacturing process, but not by compromising the security and stability of your products. With the right carton packing machines, you can streamline the end-of-line process, drive down costs, protect product integrity and create scalable production environments ready for future growth.

Robopac USA can help you enhance your packaging operations, boost your ROI and position your business for long-term success. Contact us for a quote on suitable automated packing solutions tailored to your needs to transform your production line and deliver measurable results.