There is no such thing as a “typical” manufacturing production line. Each plant has its own footprint, throughput goals, and downstream requirements. However, many operations managers and packaging engineers looking to improve their workflow ask the same question when they explore automation: Can packaging equipment be customized to fit my process?

The short answer is yes — and OCME USA has made that flexibility a cornerstone of its approach. Through packaging machinery customization, OCME enables you to tailor your end-of-line operations around your products, not the other way around.

What Customization Means in Packaging Equipment

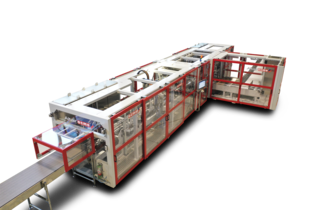

Customization in packaging machinery covers more than simple tweaks or accessories. It involves engineering systems that align with your operational goals, layout, and packaging formats while maintaining operational efficiency and scalability. When done correctly, you can improve the speed and efficiency of your system.

When you invest in custom packaging machinery, you’re adopting a system that integrates with every stage of your production line. True customization considers:

- Product Characteristics: The weight, shape, and fragility of your goods, and the overall packaging

- Line Configuration: Your facility’s available floor space, conveyor layout, and workflow direction

- Speed and Throughput: Your production rate targets and changeover times, and whether any additional customization can speed up the process without compromising safety

- Packaging Formats: From bottles and cans to boxes, trays, and shrink-wrapped bundles

- Automation and Data Needs: Integration of other aspects of your operations, such as plant software, IoT, or predictive maintenance systems

We understand that no two manufacturing environments are identical. While standardization delivers efficiency, flexibility delivers performance, especially for plants handling multiple SKUs and product lines.

OCME’s Customization Offerings and Capabilities

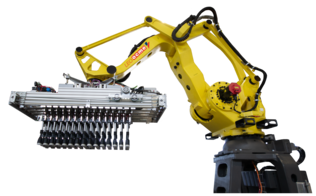

OCME USA has refined the art of flexibility through its modular packaging systems, engineered to adapt as your business grows. Rather than building one-off machines, OCME designs modular components that can be configured into fully customized solutions.

Modular Engineering

Each OCME system is built on a modular framework that allows individual units to be configured to your needs. You can scale up or reconfigure later without overhauling your entire line, making OCME machinery future-proof whenever changes are necessary. For example:

- Case packing and palletizing modules integrated in different combinations based on your packaging flow.

- Automated guided vehicles can be added later to automate material movement between stages.

- Control systems allowing data exchange across multiple production platforms.

Configurable Machinery Lines

OCME’s systems can work seamlessly, whether you need a high-speed filler, a shrink-wrapper, or a fully automated palletizing station. Each component is engineered for compatibility and communication.

Industry-Specific Adaptation

OCME’s customization extends across industries, ensuring custom packaging machines are capable of performing specific tasks while maintaining compliance with industry standards.

- Beverage and Food: Adaptable to varying volumes of bottles, cans, and cartons.

- Household Goods: Designed for irregular or lightweight packaging.

- Automotive and Lubricants: Heavy-duty handling for heavy or viscous products.

- Logistics and Consumer Products: Optimized for speed and automation.

Sustainability Integration

Today, customization also means designing for sustainable packaging solutions. OCME’s systems are engineered to minimize material waste, energy use, and downtime.

How OCME Customization Helps Solve Real Pain Points

Customization is the most effective way to solve unique manufacturing challenges. OCME USA’s configurable approach directly addresses some of the most common and costly pain points in packaging operations.

Inefficient Line Layouts

No two facilities share the same footprint. Standard machinery often requires you to redesign your space and workflows, which can be unnecessarily time-consuming and expensive. With OCME, systems are designed around your layout. This can ensure a smoother material flow and reduced bottlenecks.

Downtime and Changeover Delays

Frequent changeovers can significantly cut into output, especially for multi-SKU production lines. OCME’s machines are engineered with quick-change tooling, intuitive interfaces, and recipe-based automation. This can enable faster transitions with minimal manual intervention.

Maintenance Complexity

Generic systems often require cumbersome maintenance due to mismatched components. OCME integrates standard parts across modules, simplifying spare-parts management and technician training. This results in faster service and greater uptime.

Scalability Constraints

You might not need full automation today, but with your competitors taking advantage of innovative automation, you might need it tomorrow. Opting for a custom modular design means you do not have to purchase an entire large-scale system today. Start small and expand as your volumes grow, so your system can evolve without major disruption.

Energy and Resource Inefficiency

Customized systems eliminate redundant movement, minimize idle cycles, and reduce waste. In the long term, this means lower operational costs and higher sustainability performance. This can be a key advantage for any production manager under ESG mandates.

Implementation Strategy and Best Practices

Consider implementing customized packaging solutions as an investment in a strategic integration project. Your success depends on collaboration, planning, and adherence to proven best practices.

Define Measurable Goals Early

Before customization begins, identify the metrics that matter most: throughput, changeover time, Overall Equipment Effectiveness, labor savings, or sustainability impact. Clear metrics allow OCME engineers to tailor the design precisely to your performance targets.

Collaborate Across Departments

Customization works best when your teams, from production and maintenance to quality control and IT, are aligned from the start. Input from each function helps ensure the system fits into your broader operational ecosystem, not just the packaging line.

Embrace Digital Simulation

OCME’s engineering process often involves virtual modeling and line simulation, which helps visualize layouts and throughput before installation. This reduces implementation risk and ensures the system aligns perfectly with your plant’s workflow.

Plan for Operator Training and Lifecycle Support

A new system is only as strong as the team that runs it. OCME provides on-site and remote training and a lifecycle service program that includes predictive maintenance, parts support, and performance audits.

Ensure Integration Compatibility

Because OCME systems are designed for interoperability, they can connect to your existing MES, SCADA, or ERP software. However, integration success still depends on how you provide accurate data mapping and communication protocols. OCME’s engineering team can help verify compatibility before commissioning.

Adopt a Phased Rollout

For complex manufacturing environments, it’s often best to implement new custom workflows in stages. Start with a single machine or section, validate performance, and then expand to full-line integration. This phased strategy reduces risk, minimizes disruption, and allows continuous improvement between phases.

Risks, Limitations, and Mitigations

While custom packaging machinery provides significant benefits for your workflow productivity, it’s crucial to address common customization challenges. Taking steps to mitigate them helps you understand the limitations of your system and decide how to prevent any complications.

Higher Initial Investment

Customized systems can carry a higher upfront cost compared to off-the-shelf machinery. However, this cost is offset by higher efficiency, lower downtime, and longer equipment lifespan – all of which can provide better value in the long run. OCME supports clients through detailed ROI analyses to quantify the long-term gains.

Longer Lead Times

Designing and engineering tailored systems naturally takes longer than ordering standard equipment. OCME maintains modular design templates and established component libraries to minimize disruption, allowing faster configuration without compromising quality.

Integration Complexity

Customization often involves connecting new equipment to existing systems, which can create interoperability challenges. OCME mitigates this through standardized communication protocols, such as OPC UA and Ethernet/IP, and rigorous pre-installation testing.

Operator Learning Curve

Customized systems introduce new interfaces and workflows that may initially slow down operators. To address this, OCME provides comprehensive training, intuitive HMI design, and on-site commissioning support, all of which ensure effective user adoption.

Maintenance Adaptation

Customized equipment requires precise knowledge for maintenance and troubleshooting. OCME addresses this through its after-sales service, remote monitoring, and spare-parts programs, ensuring that your system remains optimized throughout its lifecycle.

Scope Creep and Misalignment

Expanding requirements can risk delays or budget overruns in any customization project. OCME’s structured project management framework uses milestone reviews and digital design validation to align your system with agreed-upon specifications and delivery schedules.

Why OCME’s Approach Works

Customization succeeds when it balances flexibility with reliability. OCME’s success lies in its hybrid engineering philosophy: modular standardization at the component level and full configurability at the system level.

This approach ensures that every solution is:

- Tailored to your product and space constraints.

- Scalable so that you can add capacity or new packaging formats over time.

- Efficient, with automation that minimizes manual intervention.

- Connected, ready for Industry 4.0 integration and remote diagnostics.

- Supported, with lifecycle services available across North America.

OCME’s systems provide the agility of custom engineering with the reliability of proven, standardized modules. This is an ideal combination for manufacturers aiming to modernize their end-of-line operations.

Improve Your Workflow With Customized Solutions

Can packaging equipment be customized? Absolutely. And with OCME, customization isn’t a compromise; it’s a catalyst for performance.

Investing in OCME packaging solutions means optimizing your production ecosystem for flexibility, speed, and sustainability. Our modular packaging systems can adapt to your unique challenges and deliver measurable results. From concept to commissioning, OCME USA can work with your facility to design, install, and support packaging systems that deliver precision, reliability, and long-term value.

If you’re ready to explore how customized automation can transform your operations, connect with OCME’s engineering experts today.