Retailer and regulatory packaging requirements increasingly determine how products move through supply chains. Each retailer defines exact standards for case size, labeling, pallet configuration, and sustainability performance — rules that must be followed precisely to prevent chargebacks, delivery delays, or rejected loads.

Maintaining compliance at that level of detail is difficult to achieve through manual oversight alone. It calls for end-of-line automation that ensures accuracy at speed, adapts quickly to product or format changes, and provides the traceability needed for audit and quality control.

This article examines the structure of retail packaging standards and explains how OCME’s packaging and logistics technologies support consistent, scalable compliance across modern production and distribution environments.

Understanding Retailer Packaging Requirements

Retailer packaging compliance covers every layer of your product’s journey, from the individual unit to the case and pallet. Each retailer defines how products must be prepared, labeled, and delivered to ensure they move seamlessly through automated distribution centers and reach store shelves without interruption. These requirements appear in vendor manuals, routing guides, and chargeback policies, all written with one purpose: consistency.

While the details vary from retailer to retailer, most share a common set of expectations:

Dimensional Accuracy and Stability

This defines how your packages fit together and how they withstand handling. Retailers specify pallet height limits, overhang allowances, and stacking rules to maintain uniformity and reduce product damage during transport.

Labeling and Identification

Ensure every product is traceable with barcodes and 2D codes. These must be readable at the first scan, positioned in the same location on every case or pallet, and aligned with global standards such as GS1 to support automated receiving.

Damage Prevention

Focuses on protecting products throughout the supply chain. Packaging materials, film tension, and case strength must prevent crushing, tearing, or load shifting, which can result in costly rework or rejected deliveries.

Sustainability Expectations

These are now embedded in most retail specifications. You’re asked to use less material, minimize film or corrugate where possible, and demonstrate recyclability or reduced carbon impact without compromising protection or efficiency.

Channel-Specific Readiness

Reflects the diversity of today’s retail formats. The same product may require a club pack for warehouse retailers, a shelf-ready case for supermarkets, and an e-commerce configuration for direct fulfillment. Each variant must meet its own packaging and labeling rules while maintaining production efficiency.

Traceability and Data Capture

Retailers increasingly expect transparent product movement from the production line to their distribution centers, supported by lot coding, serialized pallets, and electronic data exchange that speeds receiving and reconciliation.

Translating these standards into day-to-day production is a continuous challenge. The more manual your end-of-line processes, the greater the risk of drift and error, especially when specifications change or new SKUs are introduced.

The most effective approach is to embed retailer requirements directly into your packaging systems, allowing automation and intelligent controls to enforce compliance as part of your everyday workflow.

OCME’s Capabilities and Solution Portfolio

OCME USA delivers advanced end-of-line automation built to meet the operational and compliance demands of North American manufacturing. Each of the OCME packaging solutions is designed for precision, integration, and scalability, from filling and packaging to palletizing and internal logistics. These are all essential capabilities when working across multiple retail channels with varying packaging requirements.

Based in Georgia and backed by a global network, OCME USA combines engineering expertise with localized service and support. The result is a single-source partner for customized packaging automation, offering:

- Weight-based filling systems for viscous products such as lubricants and edible oils, engineered for high-speed output and MID-certified accuracy

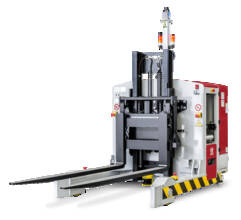

- Secondary packaging solutions, including shrink-wrap, wrap-around, and pick-and-place case packers, are designed to handle a variety of SKUs, formats, and changeover frequencies

- Robotic and conventional palletizing systems, adaptable to space constraints, load stability targets, and mixed-SKU configurations

- Laser-guided vehicles (LGVs) that automate material handling between production, warehouse, and shipping zones, reducing manual movement and improving traceability

- Integrated control and monitoring software for recipe management, quality tracking, and system performance visibility

These systems are built to function as a unified platform, not isolated machines. That coordination allows you to enforce retailer-specific packaging requirements directly through your end-of-line automated packaging equipment and workflows. Whether you’re scaling a new product line or adapting to updated retailer specs, OCME USA provides the tools, engineering, and support to keep compliance built into the process.

How OCME Solutions Address Specific Retailer Requirements

Packaging compliance begins at the machine level but extends into data handling, traceability, and predictive accuracy. OCME’s systems help address retailer mandates across four key dimensions:

1. Dimensional Accuracy and Load Stability

Retailers demand tight tolerances on pallet height, footprint, and weight. These factors impact racking, truck loading, and warehouse automation. OCME’s robotic palletizers, such as the Pegasus series with layer or row grippers, construct highly stable loads. Algorithms govern product orientation and interlayer consistency, adapting dynamically to different SKU formats.

For high-speed lines, models like Orion Advance and Perseus offer precision at scale. Palletizing systems integrate with end-of-line conveyors and upstream packers to ensure continuous flow and reduce bottlenecks, even in space-constrained layouts.

2. Traceability and Barcode Legibility

Labeling accuracy is non-negotiable when it comes to consumer transparency and inventory control. Misplaced or unreadable barcodes can trigger chargebacks or loss of trust from the retailer. OCME integrates vision inspection systems and automated label applicators into its packaging lines, ensuring 100% barcode visibility and alignment with ERP-generated data.

Moreover, the machines can interface directly with warehouse management systems (WMS) and manufacturing execution systems (MES), ensuring SKU-level data synchronization across platforms. This is critical for industries that need mixed pallets or display-ready units.

3. Sustainability and Packaging Reduction

Retailers are increasingly enforcing packaging waste thresholds. Requirements often include reduced plastic usage, recyclable films, and optimization for shelf-ready packaging. OCME’s case packers and shrink wrappers, such as the Altair wrap-around case packer or Vega HT film packer, support both film and carton packaging, with options for hybrid configurations.

These machines are engineered to reduce material usage without compromising product protection. Combined with smart palletizing and automated stretch-wrapping, OCME systems allow manufacturers to meet rigid sustainability KPIs while minimizing total cost of ownership.

4. Format Flexibility and SKU Responsiveness

Retailers regularly update display standards and promote seasonal SKUs that require line reconfiguration. With OCME’s modular machines, changeovers can be completed with minimal downtime. For example, the Gemini HT combi machine integrates shrink-wrap and wrap-around capabilities in one system, allowing rapid shifts between formats.

Likewise, Auriga series LGVs enable intelligent transport between zones or lines without physical conveyor extensions. This flexibility supports agile manufacturing setups, where a single facility may serve multiple retail formats or geographies.

Implementation and Best Practices

Success in retailer packaging compliance is not merely a function of acquiring advanced machinery. Implementation strategies and integration practices are just as critical. OCME supports a staged approach to system rollout and compliance alignment:

Audit and Requirements Mapping

Before implementation, it’s important to analyze each retailer’s packaging guidelines alongside current production capabilities. OCME’s technical teams collaborate with operations teams to identify gaps in pallet configuration, label placement, and secondary packaging.

This stage often includes simulation of line behavior using digital twins or software emulators, reducing risk during commissioning and offering visibility into how SKUs will behave downstream.

Seamless System Integration

OCME systems are designed to fit into existing infrastructures. Whether retrofitting a single packaging module or building a full end-of-line from scratch, OCME provides layout planning, utilities engineering, and software interface development. Mechanical, electrical, and digital interfaces are all designed for minimal disruption to ongoing operations.

Operator Training and Predictive Support

Compliance depends on uptime. OCME offers 24/7 technical assistance, along with operator training to ensure that production teams can execute changeovers, troubleshoot alerts, and maintain system integrity. Integrated sensors and data collection modules support predictive maintenance, reducing the likelihood of unplanned downtime that could jeopardize shipment timelines.

Risks, Challenges, and Mitigation

Even with automation in place, packaging compliance carries several operational risks. Common failure points include:

- Incorrect label placement

- Film tearing or incomplete shrink wrapping

- Non-compliant pallet height or overhang

- Barcode duplication or data mismatches

- SKU misalignment during changeovers

Each of these risks can result in failed audits or product rejections at the retail distribution center.

OCME’s equipment addresses these challenges with built-in safeguards. Vision systems reject non-compliant units before palletization. Feedback loops from sensors detect irregular wrapping patterns. Labeling stations are synchronized with line speed and ERP updates, minimizing manual intervention.

Additionally, LGVs reduce human handling during warehousing transitions, lowering the risk of load damage. Their navigation algorithms and load sensors ensure precise pallet placement during storage and dispatch.

For continuous improvement, OCME systems provide traceability logs and event history data that can be used during internal audits or retailer inquiries. This level of visibility is a differentiator in a compliance-focused supply chain.

Building Compliance Into Your End-of-Line Strategy

From dimensional accuracy and barcode readability to sustainability metrics and rapid format changes, the demands placed on your packaging operations are growing more complex with each retail partnership.

OCME USA helps you manage that complexity with integrated systems engineered for precision, flexibility, and traceability. Whether you need to automate a single step or reconfigure your entire end-of-line packaging technology, OCME offers the tools and expertise to align retail packaging standards with production reality.

To see how OCME USA can help you meet retailer packaging requirements with greater speed and accuracy, contact us to start designing solutions tailored to your operation.