Maximizing throughput and protecting products during transport are critical objectives in high-volume production environments. Automatic shrink-wrapping machines help you achieve both by securely sealing products in film and preparing them for final distribution.

These machines offer consistent wrapping quality, reduced labor dependency, and seamless integration into end-of-line packaging systems. In this blog post, we’ll explain how automatic shrink wrappers work, the benefits of shrink-wrapping across industries, and why investing in this technology can enhance operational efficiency, product integrity, and long-term ROI.

What Is an Automatic Shrink-Wrapping Machine?

An automatic shrink-wrapping machine is a high-speed packaging solution that wraps products in heat-sensitive plastic film. Once wrapped, the product passes through a heat tunnel that shrinks the film tightly around the item or multipack, creating a secure, tamper-evident, and durable package. Unlike manual or semi-automatic methods, these systems handle the wrapping process with minimal operator involvement, offering speed, consistency, and scalability.

Automatic systems are a key component of modern shrink-wrapping automation, often integrated at the end-of-line production stage. These machines are used across industries, from food and beverage to pharmaceuticals and industrial goods, to ensure packaging durability and efficient handling during transport.

This guide will explore how automatic shrink-wrapping machines work, break down their key components, and highlight the operational benefits that make them essential for modern manufacturing and distribution lines.

How Does a Shrink-Wrapping Machine Work?

Automatic shrink-wrapping machines form a secure uniform wrap seamlessly during processing. While specific configurations may vary by model and application, most shrink-wrap equipment for manufacturing operates through a series of coordinated stages designed to maintain speed, accuracy, and product integrity.

1. Product Infeed and Collation

Products enter the machine either individually or in grouped sets. Automatic infeed systems align and orient products for consistent wrapping. This step is synchronized with upstream machinery in high-speed operations to ensure continuous flow.

2. Film Dispensing

Plastic shrink film, typically polyethylene or polyolefin, is unwound and positioned around the product. The machine automatically adjusts the film size based on the product dimensions, reducing material waste.

3. Sealing

Once the film encloses the product, it is sealed using a heat-sealing mechanism such as a constant or impulse sealer. Depending on the configuration, this can include cross-seals and side-seals in full enclosure systems.

4. Heat Shrinking

The wrapped product moves into a shrink tunnel, exposing it to carefully controlled heat. The film shrinks uniformly around the product, forming a tight, tamper-evident package that conforms to its shape.

5. Discharge

After exiting the tunnel, the finished product is conveyed to downstream packaging processes such as case packing or palletizing, often within OCME USA end-of-line packaging systems.

Key Components of a Shrink-Wrapping System

An automatic shrink-wrapping machine must operate with precision, coordination, and durability to deliver consistent results in fast-paced manufacturing environments. Each system is built from a combination of core components to ensure smooth product flow, reliable film application, and secure final packaging. Understanding how each part contributes to overall performance is essential when evaluating shrink-wrap equipment for manufacturing.

Here’s a closer look at the major system elements:

Automatic Infeed Conveyors

These conveyors manage the seamless entry of products into the wrapping zone. They are engineered to regulate product spacing and orientation, minimizing jams and misfeeds. In high-speed systems, infeed conveyors often synchronize with upstream equipment to maintain continuous operation and reduce buffer times.

Film Unwind Units

The film unwind mechanism precisely dispenses shrink film, typically polyethylene or polyolefin. Equipped with tension control and film tracking systems, it ensures the material feeds smoothly without wrinkles, slack, or misalignment. Advanced unwind units also accommodate different film widths and adjust automatically to product size, improving wrapping accuracy and material efficiency.

Sealing Mechanism

Heat sealing is one of the most critical steps in the process. The sealing bar or rotary system fuses the film ends together to create a secure enclosure. Clean, consistent seals are essential for package integrity, especially during transport or stacking. Some machines offer multi-point sealing for full enclosures or complex wrap formats.

Heat Shrink Tunnel

After sealing, the product moves into a temperature-controlled tunnel. Heated air circulates to shrink the film tightly around the product or bundle, conforming to its shape. A well-designed shrink tunnel provides even heat distribution, energy efficiency, and customizable temperature profiles to suit different film types and product sensitivities.

Programmable Logic Controller (PLC)

The PLC acts as the system’s brain, managing timing, temperature, product detection, and error handling. It ensures that each component operates harmoniously, allowing for real-time adjustments and minimal downtime. Modern systems often feature touch-screen HMIs for intuitive control and diagnostics.

Safety Guards and Sensors

Shrink-wrapping systems include physical guards, emergency stops, and optical or proximity sensors to meet industrial safety standards. These features protect personnel, prevent equipment damage, and ensure the machine stops or alerts operators in case of anomalies such as film jams or product misfeeds.

Together, these components form the backbone of an efficient shrink-wrapping system. The level of engineering and integration in each element can vary, so choosing a trusted solution, like those offered in OCME USA’s automatic shrink-wrap systems, can make a critical difference in performance, uptime, and packaging consistency.

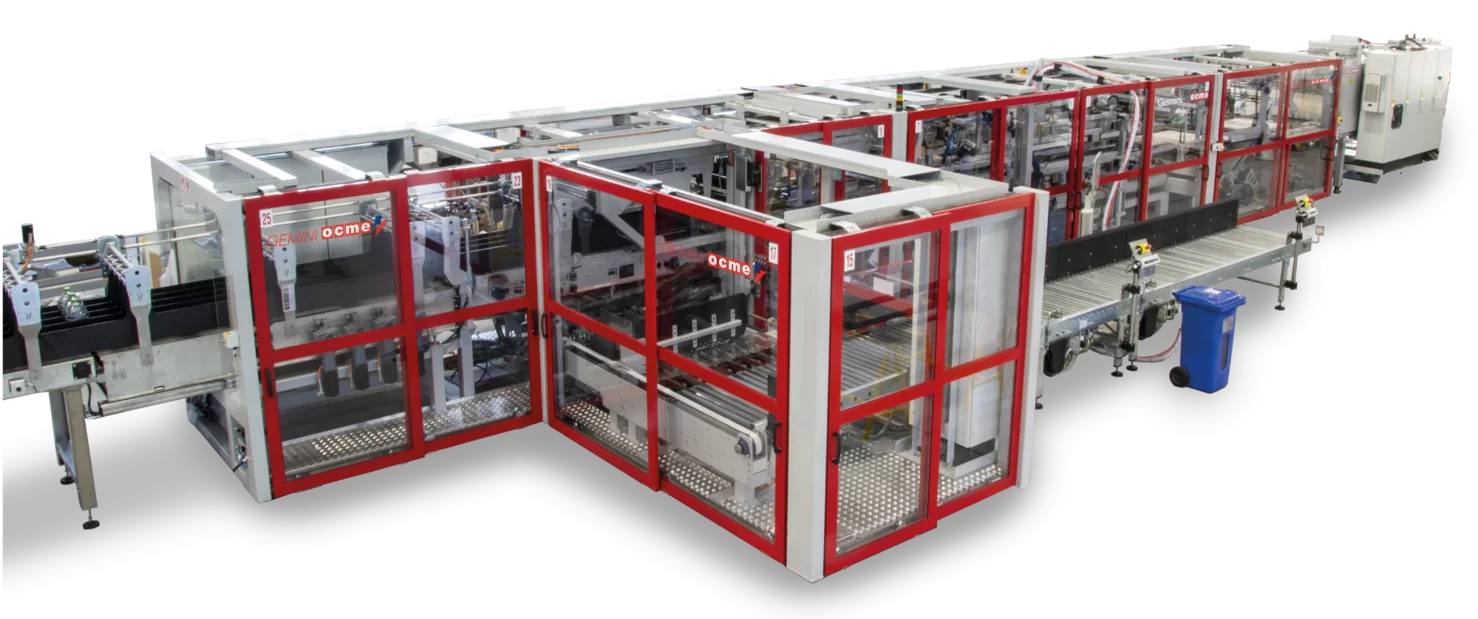

Featured OCME USA Shrink-Wrap Systems

OCME USA USA offers industry-leading solutions for shrink-wrapping automation, with models tailored to different application needs. Two standout systems include:

Spiror BW Series

The Spiror BW is a compact, high-speed rotary ring wrapper designed for automatic bundling and spiral wrapping. It is ideal for multipacks or cylindrical products and ensures minimal film use while maintaining superior load stability.

Key Highlights:

Fully automatic operation

Adjustable rotation speed for delicate or fragile items

Ideal for grouped retail or promotional packages

Integration-ready with end-of-line systems

Genesis Futura XL

The Genesis Futura XL is a fully automatic rotary ring wrapper engineered for heavy-duty, high-volume production environments. Its platform-free design enables high-throughput pallet wrapping with reduced cycle times while producing minimal mechanical stress.

Key Highlights:

Up to 135 pallets/hour

Reduced film usage with stretch control

Minimal maintenance with brushless motors

Engineered for 24/7 industrial applications

Both systems demonstrate the strength of OCME USA shrink-wrap systems in delivering precise, repeatable, and energy-efficient shrink-wrapping performance.

Benefits of Shrink-Wrapping Automation

Investing in shrink-wrap equipment for manufacturing brings measurable advantages across your packaging operations. They help enhance packaging consistency and efficiency across the entire end-of-line process.:

Higher Throughput: Automatic machines operate faster than manual or semi-automatic systems, making them ideal for high-volume environments.

Improved Product Protection: Tightly sealed shrink film provides enhanced resistance to dust, moisture, tampering, and handling damage during transport and storage.

Labor Optimization: Automating repetitive tasks reduces labor costs and operator fatigue while reallocating skilled workers to more strategic roles.

Packaging Consistency: Automated equipment ensures uniform wrapping across batches, supporting brand integrity and reducing rework.

Material Efficiency: Advanced film control systems minimize waste by optimizing film usage per unit, helping lower material costs and meet sustainability goals.

End-of-Line Integration: Shrink-wrap machines like those from OCME USA are designed to work with other high-speed packaging solutions, including case packers and palletizers, to streamline your production line from start to finish.

Why Choose an Automatic Shrink-Wrapping Machine Over Manual or Semi-Automatic Options?

Manual and semi-automatic shrink-wrapping solutions can benefit small-scale operations, but they often introduce limitations that become more apparent as your production demands grow. These systems rely heavily on manual labor, are prone to inconsistencies, and can create operational bottlenecks that slow down throughput and inflate labor costs as your operations scale.

Automatic shrink-wrapping machines address these challenges by eliminating repetitive manual tasks and ensuring standardized, high-quality output. They also support long-term scalability by integrating seamlessly with other end-of-line systems such as palletizers and case packers.

If you're experiencing inconsistent wrap quality, labor-intensive packaging, or difficulty meeting growing demand, automatic high-speed packaging solutions, like those provided by OCME USA, can provide the speed, precision, and reliability required to elevate your packaging performance and streamline operations.

Is Shrink-Wrapping Right for Your Products?

Shrink-wrapping is a highly versatile packaging solution that accommodates various product types, sizes, and configurations. Manufacturers can use it to bundle consumer goods, unitize industrial components, or secure pharmaceuticals for transport.

Products that benefit most from shrink-wrapping include:

- Bundled beverages and canned goods requiring tamper-evident, moisture-resistant packaging

- Pharmaceutical and nutraceutical products that demand hygienic sealing and traceability

- Consumer electronics and hardware where visibility and protection during handling are essential

- Packaged foods like frozen meals or snack multipacks need secure containment and shelf appeal

- Industrial components that benefit from unitization for streamlined logistics

When combined with OCME USA’s advanced automation systems, it becomes a powerful tool to enhance packaging performance across your entire line.

Achieve High-Performance Packaging With OCME USA USA

OCME USA shrink-wrap systems deliver the speed, consistency, and integration you need to streamline packaging and scale with confidence.

Contact OCME USA USA today to explore how our shrink-wrap equipment can enhance your end-of-line performance and support your automation goals.