In modern manufacturing and logistics environments, speed, precision and scalability are vital. As businesses expand and customer expectations grow, traditional packaging methods often become a significant obstacle.

Manual packaging processes are typically inefficient, inconsistent and costly, creating bottlenecks that limit throughput and increase operational risk. For companies seeking to scale effectively, these inefficiencies can hinder growth, drive up labor costs and strain supply chain performance.

Packaging automation offers a proven solution to these challenges. By integrating machine packaging systems into production lines, businesses can streamline their packaging operations, eliminate manual roadblocks and establish a more consistent, efficient workflow. Automated packaging not only improves operational efficiency but also enhances product protection, reduces labor dependency and supports faster, more reliable scaling.

This guide explores how automated packaging solutions improve packaging efficiency, address labor-related challenges and help businesses build more resilient, cost-effective operations.

The Drawbacks of Manual Packaging Processes

While manual packaging is still prevalent across many industries, it introduces significant risks that are difficult to overlook. Human error, variable output quality and slower processing speeds can all undermine your production goals. Additionally, labor-intensive packaging methods also come with rising costs, especially as workforce shortages and wage increases put added pressure on operating budgets.

When labor accounts for a large share of packaging expenses, companies struggle to scale efficiently. Delays at the end of the production line create downstream issues that affect shipping, storage and inventory management. As a result, many organizations are exploring how to improve packaging efficiency without increasing headcount.

Improving Packaging Efficiency With Automation

For companies focused on improving packaging efficiency, automation offers a measurable path forward. Instead of manually adjusting equipment or troubleshooting errors mid-shift, your packaging systems run according to programmed specifications. Modern machines are designed to handle a wide variety of products, carton sizes and wrapping styles with minimal downtime.

Key ways that automated packaging solutions enhance efficiency include:

- Faster cycle times and increased throughput

- Fewer product defects or packaging inconsistencies

- Automated error detection and adjustments

- Integration with upstream and downstream systems for better flow

When companies invest in machine packaging, they build resilience into their operations. Fewer delays, fewer quality issues and faster fulfillment times allow businesses to consistently meet customer expectations.

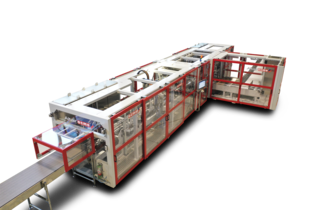

Types of Automated Packaging Solutions

There are several types of automated packaging solutions available today, each designed to meet specific production needs. Some of the most common technologies include:

Stretch Wrappers

Stretch wrapping machines quickly and securely wrap pallet loads, improving load stability and reducing the need for manual labor. Automated stretch wrappers can apply pre-set tension and film coverage, ensuring each load meets shipping requirements.

Shrink Wrappers

Shrink wrapping machines enclose products in a protective plastic film, then apply heat to create a snug, tamper-resistant seal. This process protects goods during transport and enhances product presentation.

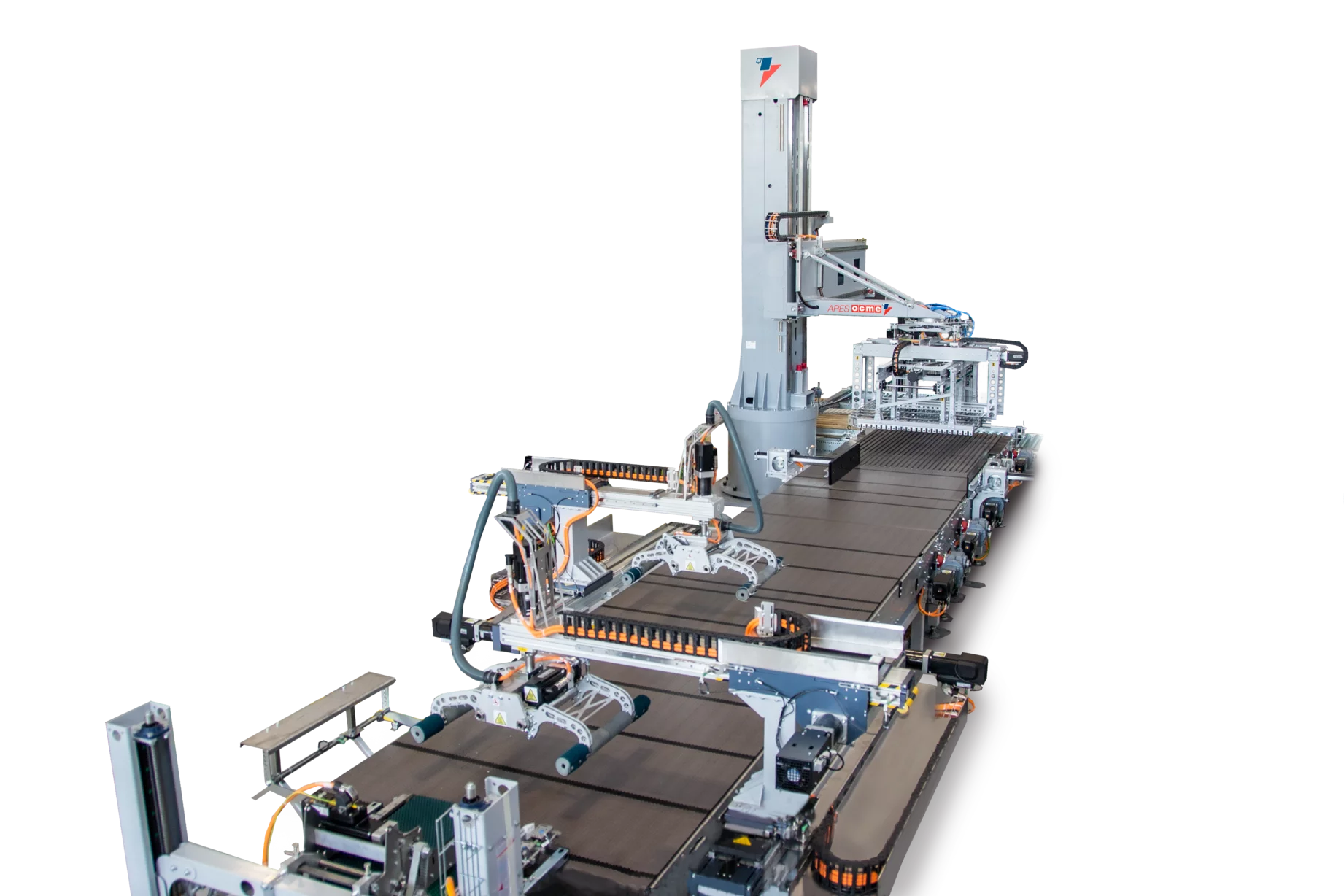

Palletizers

Automated palletizers stack boxes, bags or containers onto pallets with precision. They optimize space usage, reduce the risk of worker injury and improve shipping efficiency.

Choosing the right combination of machine packaging technologies depends on your product types, production volumes and operational goals.

Automated Guided Vehicles (AGV’s)

Automated guided vehicles are autonomous forklifts. These machines automate the forklift process by removing the forklift driver component. AGV’s pick up pallets and move them easily throughout your facility to a staging area or to a trailer for shipment.

How Machine Packaging Streamlines Operations

Machine packaging replaces time-consuming and repetitive manual steps with precise, programmable performance. From case erecting and shrink wrapping to palletizing and stretch wrapping, today’s automated packaging solutions cover nearly every stage of the process.

Instead of relying on workers to tape boxes or stack products, machines handle the tasks at higher speeds and with greater consistency. Companies that invest in packaging automation find they are able to reduce labor costs in packaging significantly while also minimizing errors, rework and product damage.

Recent industry data shows that automated packaging systems can increase throughput by up to 30% compared to manual processes, helping manufacturers meet tighter deadlines without expanding their labor requirements. Similarly, error rates for automated packaging systems are up to 50% lower than those for manual handling, reducing waste, returns and customer dissatisfaction.

Key benefits of machine packaging include:

- Consistent application of wrapping, sealing or strapping

- Faster throughput rates compared to manual labor

- Improved packaging integrity for shipping and storage

- Fewer bottlenecks during peak production times

By removing the variability that comes with human labor, machine packaging systems help manufacturers deliver products faster, safer and more reliably.

How Packaging Automation Reduces Labor Costs

One of the most significant advantages of packaging automation is its ability to reduce labor costs in packaging. Machines can perform repetitive tasks without fatigue, break times or overtime pay. This shift allows your workforce to move into higher-value roles such as quality control, maintenance or logistics management.

According to a study by The Association for Packaging and Processing Technologies (PMMI), companies implementing packaging automation see an average 20% to 30% reduction in labor costs within the first year. Furthermore, companies with highly automated packaging lines experience 15% fewer workplace injuries, reducing workers’ compensation claims and minimizing operational disruptions.

Automation doesn’t necessarily eliminate jobs; it reallocates human resources toward more strategic tasks. Companies that implement automated packaging solutions often find that they can avoid hiring additional workers as they expand. This not only saves on wages but also reduces onboarding, training and HR management expenses.

Examples of labor-related cost savings include:

- Lower headcount requirements on the packaging line

- Decreased turnover rates due to less physical strain

- Fewer injury claims related to repetitive motions

- Predictable operating expenses that support long-term planning

By relying on machine packaging, companies position themselves to stay competitive in tight labor markets without sacrificing output or quality.

How to Start the Transition to Automated Packaging

Starting with machine packaging doesn’t mean overhauling your entire production line at once. Many companies begin with a single automated station, such as a case erector or stretch wrapper, before expanding to other areas.

Steps to a successful automation journey:

- Assess Current Processes: Identify bottlenecks or inefficiencies in your existing packaging operations.

- Define Goals: Clarify whether your priority is reducing labor costs, packaging costs, improving packaging efficiency or both.

- Consult with Experts: Work with packaging automation specialists to design a phased approach that fits your budget and operational needs.

- Pilot a System: Start with one area of automation and track the results before scaling up.

- Train Your Team: Invest in proper training to maximize the effectiveness and longevity of your new equipment.

Taking a strategic, step-by-step approach allows you to manage costs, minimize disruption and maximize the value of your investment.

Key Considerations When Investing in Packaging Automation

Before adopting packaging automation, it’s important to evaluate several factors to ensure a successful transition:

Product Variety: Not all automated systems are built for every product type. Assess the range of sizes, shapes and packaging materials your operation handles. Flexible solutions that accommodate a variety of SKUs will future-proof your investment and prevent costly customizations.

Production Volume: Facilities with higher production volumes typically benefit more from fully automated systems, while smaller operations may find that semi-automation delivers an optimal balance between cost and efficiency. Accurately forecasting production growth is essential when determining the right level of automation.

Floor Space: Automated equipment requires sufficient floor space not only for installation but also for safe and efficient operation. When planning layouts, companies must consider equipment footprints, operator access points and potential future expansion.

Integration: Seamless integration with existing conveyors, robotics, warehouse management systems and ERP platforms ensures that packaging automation becomes a fully connected part of the production flow rather than a standalone process.

Scalability: Choose automation systems that can grow with your business. Modular equipment designs and upgradable platforms provide flexibility as production demands evolve.

The Long-Term ROI of Machine Packaging

Although the upfront cost of automation can be significant, the long-term ROI is clear. Companies can recoup their investment through:

- Labor cost savings

- Fewer product defects and returns

- Faster order fulfillment

- Improved operational reliability

Beyond cost savings, packaging automation provides strategic advantages. It reduces dependence on manual labor markets, enhances operational resilience and allows for faster, more predictable scaling. Businesses that commit to automated packaging solutions position themselves for more substantial margins, faster lead times and greater customer satisfaction.

Automate Your Packaging Operations With OCME USA

Companies that invest in machine packaging are building smarter, faster and more cost-effective operations. By implementing packaging automation, businesses can reduce labor costs in packaging, improve packaging efficiency and meet rising demands with confidence.

OCME USA delivers the industry’s most advanced automated packaging solutions, helping manufacturers maximize efficiency and control costs. Whether you are looking to integrate a single machine or develop a fully automated line, OCME USA provides the expertise and innovation to support your growth.

Ready to transform your packaging operations? Contact OCME USA today to learn how machine packaging can drive real results for your business.