Unplanned downtime is one of the most expensive problems manufacturers face. In high-volume industries like beverages, food, and consumer goods, even a short interruption in production can lead to higher production costs and missed orders. This, in turn, negatively impacts customer experience. That's why more facilities are seeking equipment partners to engineer solutions for continuous operations.

OCME USA, part of the Aetna Group, designs and supports end-of-line systems that keep packaging lines running at peak performance. Our solutions feature durable machine construction, modular design, integrated logistics, and other capabilities that prevent costly downtime.

Our customers also benefit from operator training, service, and monitoring tools that extend machine life and reduce stoppages. These strengths allow manufacturers to maximize packaging automation uptime in high-volume environments.

This article explores how OCME USA systems are engineered for maximized uptime and why manufacturers are turning to OCME systems for 24/7 operation support.

24/7 Reliability as a Manufacturing Imperative

Global supply chains now operate on tighter schedules and higher volumes. Production lines are expected to handle frequent SKU changes, seasonal demand spikes, and extended campaigns with fewer breaks in between (if any).

When production stops unexpectedly, the ripple effects are widespread and immediate:

- Lost output

- Missed shipping windows

- Higher production and marketing costs

- Strained relationships with retailers and distributors

These repercussions carry heavy consequences that lead to unplanned downtime, costing manufacturers an estimated $50 billion annually, according to Emerson.

Packaging lines are especially vulnerable because they sit at the final stage of production. Any delay in packing, wrapping, or palletizing prevents finished goods from moving to the warehouses or customers, creating bottlenecks across the supply chain.

Manufacturers face new pressures that test the limits of their packaging systems, such as:

- Frequent Changeovers: Beverage and consumer goods producers often run seasonal SKUs, multiple package sizes, and short promotional campaigns.

- Retail Expectations: Large distributors measure on-time performance closely and penalize missed delivery windows.

- Consumer Demand: Shoppers expect immediate product availability, leaving little tolerance for stockouts or delays.

OCME USA's Response

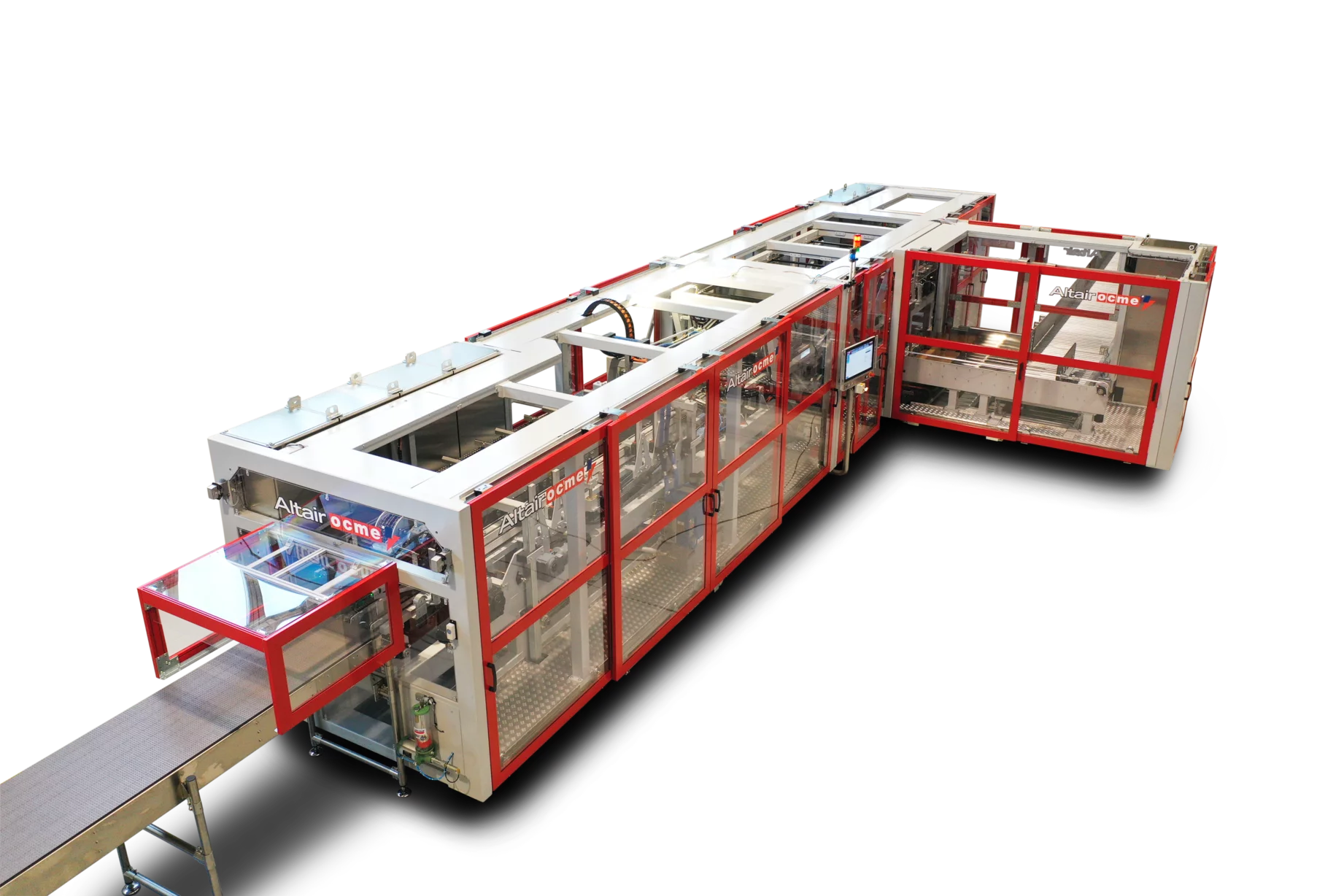

OCME USA helps our customers overcome these pressures with systems designed for reliability and durability. For instance, the Altair wrap-around case packer and Auriga Laser-guided Vehicles (LGVs) can be integrated into packaging lines, supporting continuous performance while adapting to changing operational needs.

Our solutions empower manufacturers to maintain reliable end-of-line operations even under the demanding conditions of 24/7 production.

Continuous Support Infrastructure

A significant factor in sustaining continuous operation is having a dependable support network that ensures access to parts, upgrades, and technical expertise. This prevents or minimizes downtime due to equipment failure and helps teams keep production schedules on track.

A global service framework ensures that OCME systems, built for 24/7 operation, have the parts and expertise needed to stay online even during demanding production schedules.

OCME USA's service framework gives manufacturers confidence that their lines will remain supported across the entire equipment lifecycle. It provides several advantages, including:

- Spare Parts Availability: Logistics programs keep essential components easily accessible, reducing the time required to repair equipment and restore production in case of a breakdown.

- Lifecycle Management: Retrofits, software updates, and equipment upgrades help extend machines' lifespans and enhance their capabilities.

- Service Coordination: Global expertise and U.S.-based support ensure faster responses to customer needs.

Support in Practice

OCME's global service network is especially valuable for high-performance systems that are expected to operate continuously. For instance:

- Auriga LGVs rely on battery management and navigation systems that benefit from scheduled checks and timely parts availability.

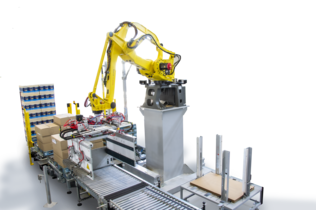

- Pegasus palletizers achieve high throughput when wear components are replaced on schedule and supported by expert service.

This combination of robust equipment design and responsive service resources helps manufacturers sustain uninterrupted performance in 24/7 environments.

OCME USA Technical Support and Remote Assistance

OCME USA complements on-site service with advanced monitoring and diagnostic tools. For example, Auriga LGVs are equipped with "The Supervisor," an AGV manager system that "defines, monitors, forecasts, and archives" operational parameters.

This system enables remote visibility into logistics operations and detects issues before they interrupt production. Operators can see the status of every vehicle via the visual interface.

Customers also benefit from other capabilities of OCME USA devices, such as:

- Performance Tracking: OCME equipment includes digital supervision tools that monitor parameters such as load activity and energy usage, helping packaging teams evaluate efficiency over time.

- Faster Troubleshooting: Remote diagnostic services allow technicians to access system data without waiting for an on-site visit, reducing the duration of downtime events.

How Remote OCME USA Technical Support Increases Uptime

Remote adjustments to operating parameters can benefit systems like the Altair wrap-around case packer and Vega HT shrink wrapper. For logistics, Auriga LGVs can be monitored in real time, ensuring safe operation and an uninterrupted flow of goods. These tools allow manufacturers to respond quickly to issues and maintain stability in end-of-line processes.

On-Site Service and Training

While remote technical support is essential, some situations require in-person expertise. OCME USA provides on-site services for installation, commissioning, and routine maintenance. Training sessions can be conducted alongside service visits to ensure operators and maintenance staff are confident in managing the equipment.

OCME USA's services include:

- Commissioning Support: Our technicians oversee startup procedures and confirm that machines are set up for the plant's conditions.

- Routine Maintenance: Scheduled visits allow technicians to identify wear points and replace components before failures occur.

- Operator Training: Staff are instructed on safe operation, line adjustments, and preventive care.

Why On-site Support Is Crucial

Technologies such as Auriga LGVs and Pegasus robotic palletizers require careful integration with plant layouts and product requirements. On-site service ensures that vehicles navigate safely within facilities and that palletizing patterns match specific load formats. Training equips operators and maintenance teams with the knowledge to manage these systems effectively, reducing the likelihood of downtime during continuous operation.

Smart Design for High Availability

The Perseus and Pegasus palletizers show how OCME designs equipment for long production runs. These machines use servo-controlled movements and heavy-duty frames, allowing them to operate at high speeds with consistent accuracy. By reducing wear during long cycles, they contribute directly to greater packaging automation uptime across end-of-line operations.

Other design features across OCME equipment include:

- Durable Components: Mechanical parts are specified for long service life under continuous use.

- Predictable Maintenance Intervals: Systems are engineered to allow scheduled servicing rather than frequent unplanned repairs.

- Accessible Design: OCME designs machines with operator access points for maintenance and adjustments.

Design and Operational Stability

When equipment is built for continuous operation, manufacturers gain the reliability they need for effective scheduling and production planning. They are less likely to cause unexpected delays, allowing facilities to meet 24/7 output targets with fewer disruptions.

Modular, Integrated Equipment

Manufacturers are moving away from patching together equipment from multiple vendors because integration gaps often create downtime. A modular, unified approach allows packaging lines to adapt to new requirements without disrupting continuous operation.

OCME designs its systems with this in mind. Case packers, shrink wrappers, and palletizers are modular in construction and operate on integrated controls that coordinate product flow across the line. This reduces mismatches at handoff points and makes format changes faster.

Examples include:

- Altair Wrap-around Case Packer: Forms cartons directly around products and adapts to multiple formats with minimal adjustment.

- Vega HT Shrink Wrapper: Configurable for different bundle types, while maintaining high throughput and efficient film usage.

- Pegasus Palletizer: Integrates with upstream equipment to balance flow, reducing bottlenecks during continuous runs.

Operational Benefits

When modular equipment is coordinated through shared controls, production teams can scale lines, swap formats, and maintain 24/7 operation with fewer stoppages. Integration also simplifies operator training since interfaces follow consistent logic across machines.

Empowering Customers Through Training and Accessible Interfaces

Operators are the ones who interact with packaging equipment day after day, so their ability to manage systems is critical to continuous operation. To support them, OCME USA offers training programs and intuitive human–machine interfaces (HMIs) that simplify adjustments and reduce the likelihood of errors.

Support for operators includes:

- Intuitive HMIs: Interfaces present data straightforwardly, with guided menus that make line adjustments easier to perform.

- Training During Installation and Service Visits: Instruction covers topics such as safe operation and troubleshooting.

- Documentation and Resources: Technical manuals and reference materials are provided to support training

Practical Impact of Training and HMIs

Systems such as the Altair case packer and Vega HT shrink wrapper are equipped with HMIs that guide operators through routine tasks and error resolution. Along with training, these tools give staff the confidence to manage machines efficiently and keep production running.

Operational Advantage Through End-to-End Integration

OCME's full portfolio extends beyond individual machines to complete end-of-line solutions. Packing, palletizing, internal logistics, wrapping, and waste-management systems are designed to work together, reducing the risks that arise when equipment from multiple vendors is combined.

Our solutions include:

- Auriga LGVs: By automating pallet movement, these vehicles reduce reliance on forklifts and improve traffic safety in production areas.

- ReCYCLE: The system compacts packaging waste at the point of generation, keeping zones cleaner and minimizing handling.

- Technoplat PW (Developed by Robopac): This turntable uses paper instead of plastic film for pallet wrapping. It gives manufacturers a lower-impact alternative without reducing throughput.

By coordinating these solutions, OCME helps manufacturers achieve higher system-wide uptime and smoother production flow.

OCME Systems for 24/7 Operation: Build Packaging Lines That Maximize Uptime

OCME USA provides equipment and services designed to keep packaging lines running 24/7. Innovative engineering, modular design, integrated logistics, and a strong service infrastructure combine to deliver high availability across every stage of the end-of-line process.

With solutions like the Altair case packer, Vega HT shrink wrapper, Pegasus palletizer, Auriga LGVs, and ReCYCLE waste system, OCME USA demonstrates how automation can sustain nonstop performance while reducing operational risk.

Discover how OCME systems enable 24/7 operation across your packaging line. Contact OCME USA today.