Unplanned downtime on high-volume packaging lines can disrupt schedules, inflate labor costs, and strain customer commitments. A single hour of stoppage in end-of-line packaging could lead to missed shipments, overtime labor, and costly recovery measures.

Preventive maintenance offers a structured way to avoid those setbacks. By inspecting, servicing, and replacing components before they fail, manufacturers can keep lines running steadily and extend equipment life.

This guide walks you through how preventive maintenance drives down costs on high‑volume packaging lines, why reliability matters at every stage, and the core elements of an effective program. It also highlights cost comparisons and explores how advanced tools such as R‑Connect support smarter maintenance decisions.

Why High-Volume Production Maintenance Is a Must

High-volume production puts continuous stress on motors, belts, rollers, and sensors. Without regular service, wear compounds quickly, and small faults can escalate into major failures. Even brief downtime can delay shipments and force teams into costly recovery efforts.

However, studies show that not all machines affect line reliability equally. In one automotive production line case study, machines were classified as most critical, secondary critical, or general. The most critical 20% of machines drove the largest share of reliability losses when failures occurred. Through targeted weekly preventive maintenance, total shutdown time was reduced to less than half a day per week while maintaining reliability above 70%.

Preventive high-volume production maintenance strategies ensure equipment stays reliable and prepared for peak demand, while a consistent schedule helps identify wear early, replace components proactively, and avoid costly production delays.

Key Cost Savings From Preventive Maintenance on High-Volume Packaging Lines

Preventive maintenance packaging lines deliver measurable savings for packaging operations. By resolving wear and performance issues early, facilities can control expenses and protect packaging equipment reliability.

- Minimized Downtime: Planned service avoids the disruptions of emergency breakdowns. Instead of halting production for unplanned repairs, worn parts are replaced during scheduled stops, keeping output consistent.

- Lower Labor Costs: Without unexpected stoppages, teams spend less time on overtime recovery shifts. This reduces labor expenses and helps prevent workforce fatigue.

- Reduced Repair Expenses: Addressing issues early keeps small fixes from becoming major overhauls. Components are replaced at a fraction of the cost compared with full system rebuilds.

- Consistent Product Quality: Regular adjustments and inspections prevent wrapping errors or damaged pallets, reducing waste and the cost of rework.

Compliance and Safety Benefits

Beyond cost savings, preventive maintenance also protects manufacturers from regulatory and safety risks. Packaging equipment reliability often falls under compliance standards such as OSHA workplace safety rules, ISO 9001 quality management, and, in some industries, FDA packaging requirements. Skipping maintenance can mean more than a broken motor — it can expose operators to hazards, invite regulatory fines, or even trigger product recalls if quality is compromised.

A structured program for preventive maintenance in packaging lines creates safer working conditions by reducing the likelihood of machine malfunctions that could injure operators or damage goods. This not only safeguards the workforce but also strengthens morale and productivity. By linking safety, compliance, and maintenance, manufacturers avoid costly liabilities and protect both people and product integrity.

Comparison of Costs

| Scenario | Downtime Hours/Month | Estimated Cost Impact |

|

Unplanned Downtime (reactive maintenance) |

15–20 hours | $75,000–$100,000 in lost output and labor |

| Preventive Maintenance (scheduled stops) | 4–6 hours | $20,000–$30,000 in controlled service cost |

Example based on industry benchmarks; actual values vary by production line scale.

Together, these measures protect throughput and extend the lifespan of packaging assets, making preventive maintenance a cost-efficient strategy for any high-volume line.

The ROI of Preventive Maintenance

Decision-makers often weigh whether preventive maintenance justifies its upfront cost. In most packaging operations, the answer is clear: it pays back quickly.

Industry benchmarks suggest that preventive maintenance programs typically cost about 2–5% of an asset’s replacement value each year. Yet they can reduce production losses by 10–15% a return that compounds over time.

Consider equipment lifespan: a well-maintained machine might remain productive for 12 years, compared with just 8 years under reactive maintenance. That four-year gain translates into avoided capital spending, lower financing needs, and steadier long-term planning.

By framing preventive maintenance as a high-return investment rather than just an expense, operations managers can secure stronger support from financial leadership.

Components of a Preventive Maintenance Program

A well-structured program combines inspections, spare parts readiness, operator training, and documentation. Grouping critical machines together for service reduces frequent shutdowns and aligns maintenance with production goals.

Regular Inspections and Diagnostics

Routine inspections identify wear and misalignment before they cause downtime. A structured diagnostic process with detailed reporting gives teams clear visibility into equipment condition. When paired with real-time monitoring and alerts, operators gain timely insight into machine health and can act before small issues develop into costly failures.

Spare-Parts Management

Keeping production lines running at peak performance requires access to reliable components that match system requirements. Using high‑quality spare parts ensures compatibility, supports consistent results, and extends equipment life.

Training and On-Site Coaching

Well-trained operators recognize early warning signs and perform daily maintenance routines. On-site coaching equips teams to manage small issues independently, reducing service calls and preventing avoidable stoppages.

Inspection Checklists and Documentation

Organized records help track service dates, replaced parts, and inspection findings. Logging service dates, replaced parts, and inspection findings allows teams to identify recurring issues, fine-tune service intervals, and plan future upgrades.

By combining these four components, inspections, spare-parts readiness, training, and documentation, manufacturers can maintain high-volume lines at peak efficiency while avoiding unnecessary costs.

Remote Monitoring and Predictive Maintenance

Remote monitoring and upgrades can take a preventive maintenance program to the next level. With the R-Connect monitoring system, manufacturers gain access to real-time remote diagnostics and data-driven maintenance planning. This enables teams to spot trends, detect early signs of wear, and schedule service before breakdowns occur, all without waiting for on-site inspections.

TPM kits and automated maintenance alerts further streamline the process by making lubrication, calibration, and troubleshooting more efficient. These tools ensure that routine care happens on schedule and that small issues are addressed before they impact performance.

OCME USA also offers retrofits and system upgrades to extend the lifespan of existing equipment and keep it aligned with evolving production demands. By combining advanced monitoring technology with upgrade support, manufacturers can maintain peak performance, reduce total cost of ownership, and keep high-volume lines operating without costly interruptions.

Applying Preventive Maintenance in Practice

Putting preventive maintenance into practice requires more than a calendar of service dates. It also demands consistent monitoring, proper documentation, and a proactive mindset to address potential issues before they escalate.

1. Criticality Analysis

A proven starting point is conducting a criticality analysis to identify the 20% of machines most responsible for downtime. By prioritizing these assets, maintenance teams gain the fastest return with the least disruption.

2. Schedule Maintenance

Scheduling should align with natural production lulls, such as weekends, changeovers, or scheduled line cleanings, so that service doesn’t interfere with peak output.

3. Maintenance Training

Finally, involving operators in daily care pays dividends. Training them to spot vibration, alignment shifts, or unusual noise provides an early-warning system that extends the reach of maintenance staff.

These steps turn preventive maintenance from an abstract concept into a structured, practical program that balances uptime with cost control.

OCME USA Preventive Maintenance Solutions

Preventive maintenance is not a one-size-fits-all process. While machine criticality, production goals, and service resources should guide scheduling, monitoring tools and service programs must align with these best practices to allow manufacturers to adapt strategies to their packaging lines.

First Maintenance Kit

Prevention is most effective when the right parts are on hand. OCME USA offers a First Maintenance Kit that equips teams with essential wear parts likely to require replacement during a machine’s lifecycle.

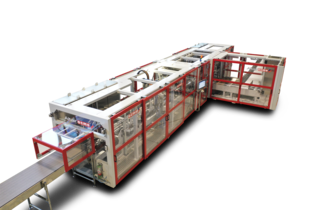

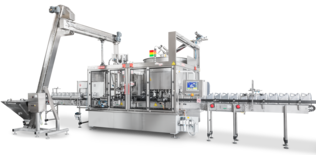

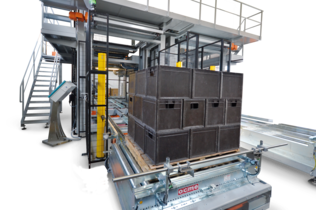

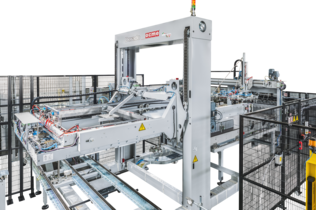

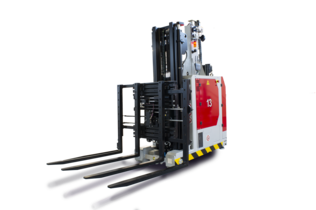

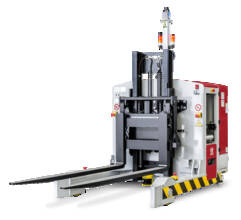

Kits are available for a wide range of products, including filling, shrink-wrapping, wrap-around, palletizing, and depalletizing solutions. By ordering these kits in advance, downtime can be minimized and production can restart quickly.

Phase-Out Replacement and Upgrades

Older components eventually reach phase-out, creating risk for production. We provide guidance on identifying these parts and offer upgrade options, from drive replacements to complete motor and control system updates.

Proactive replacement prevents failures, enables planned installation schedules, and ensures machines operate with the latest technology.

Spare Parts Supply

With a fully stocked warehouse and an efficient distribution network, OCME USA ensures quick delivery of critical spares. All parts are quality checked prior to shipment, and technical support is available to help identify and recommend the right components based on machine model and year.

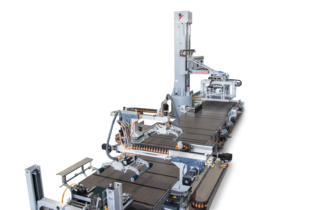

Upgrades and Retrofit

Continuous research and development mean that new technologies can benefit existing machines. We provide both standardized upgrade packages and tailored retrofit projects.

These improvements can enhance efficiency, productivity, safety, and performance while optimizing long‑term return on investment.

Achieving Preventive Maintenance Excellence With OCME USA

Preventive maintenance lowers operating costs, reduces unplanned downtime, and sustains throughput on demanding packaging lines. By combining inspections, spare-parts readiness, operator training, structured documentation, and advanced monitoring, manufacturers can keep lines reliable and cost-efficient.

We support manufacturers with genuine spare parts, tailored maintenance kits, upgrades, and after‑sales services. By working directly with OCME USA, you can strengthen packaging equipment reliability, plan ahead for component replacements, and align preventive maintenance programs with your production goals.

Contact us today to learn more about how our preventive maintenance solutions can keep your operations running smoothly.