Choosing the right industrial packaging machine directly impacts a facility’s performance. As packaging demands become more complex and throughput expectations rise, aligning equipment with operational needs affects everything from workflow efficiency to long-term profitability.

The challenge often lies not in the availability of options but in identifying the best fit. With a broad range of technologies and machine types, every selection should be guided by your facility’s specific requirements.

This guide outlines key selection factors to consider, common types of end-of-line packaging equipment, and the benefits of automation in improving consistency, efficiency, and return on investment (ROI).

The Strategic Value of Automation in End-of-Line Packaging

Automation optimizes packaging operations by improving speed, accuracy, and reliability. Instead of relying on manual labor to handle repetitive tasks, automated systems maintain consistent output across shifts and production volumes. This reduces the risk of bottlenecks and helps maintain steady throughput even during periods of high demand.

A major advantage of automation is its ability to deliver repeatable, high-quality results. Machines designed for precision packaging reduce variability, lowering the risk of product damage, mislabeling, or defects that can disrupt distribution.

Additionally, automated systems enhance decision-making through built-in monitoring tools. Sensors and software capture real-time performance data, allowing operators to track efficiency and schedule maintenance before issues arise.

While cost is always a factor, automation often pays for itself by reducing downtime, material waste, and manual interventions. For operations looking to scale efficiently, automation provides a reliable foundation for meeting evolving packaging demands.

Common Types of End-of-Line Machinery

Modern end-of-line systems are designed to bring order, speed, and accuracy to the final stages of the packaging process. From transporting products to wrapping pallets, each piece of machinery plays a specific role in improving throughput and packaging consistency. The right combination of packaging machinery technology depends on the product type, industry regulations, and operational scale.

Below is a breakdown of the most widely used end-of-line solutions across industries.

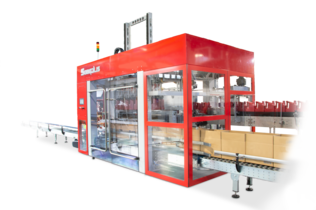

Case Handling Systems - REPLACE WITH FILLING MACHINES

Case handling systems, such as erectors, packers, and sealers, automate the formation, loading, and closing of corrugated boxes. These machines streamline the transition from primary packaging to shipping units by ensuring each case is built, filled, and sealed with precision, minimizing variability and improving packing speed.

Use Cases: High-volume production lines, particularly in food and beverage, consumer goods, and pharmaceuticals

Industry Applications: Ideal for businesses looking to eliminate manual case assembly and sealing while maintaining uniformity for warehousing and logistics

Cartoning and Tray Packing Machines

Cartoning and tray packing machines are designed to automatically insert products into pre-formed cartons or trays. These systems often incorporate product collation, orientation, and closing mechanisms, delivering secure, presentation-ready packaging ideal for consumer-facing industries.

Use Cases: Common for retail-ready packaging, especially in the food, beverage, and personal care industries where shelf presentation is critical

Industry Applications: Used across snack food lines, dairy production, frozen meals, cosmetics, and pharmaceuticals to ensure secure, visually appealing packaging.

Palletizing and Depalletizing Systems

These systems use robotic arms, gantry systems, or layer-forming conveyors to place products onto pallets, or remove them, without manual labor. Automating stacking patterns and alignment ensures stable, uniform pallet loads are ready for storage or shipping.

Use Cases: Medium to high-volume manufacturing plants and distribution centers with consistent product dimensions

Industry Applications: Widely used in beverages, home care, agriculture, and chemicals — anywhere consistent, safe stacking is required to prepare goods for transport

Shrink Wrapping and Bundling Machines

Shrink wrapping and bundling machines encase products or product groups in plastic film, which contracts tightly around the load when heat is applied. This creates a secure, protective layer that holds items together and improves shelf appearance while defending against dust and moisture.

Use Cases: Grouping multiple units (e.g., bottled water packs), protecting goods from dust and moisture, or preparing display-ready bundles

Industry Applications: Frequently used in beverages, household goods, and electronics — retailers also benefit from these machines for promotional multi-packs

Stretch Wrapping and Strapping Machines

These machines are used at the end of the packaging line to stabilize palletized loads. Stretch wrappers wrap loads in plastic film, while strapping machines apply tensioned bands, either plastic or metal, around heavy or irregularly shaped items to secure them during handling and transport.

Use Cases: Securing finished pallets to prevent shifting during transportation

Industry Applications: Logistics, warehousing, building materials, food and beverage, and paper products benefit from these machines to reduce transit damage and improve load integrity

Labeling and Coding Systems

Labeling and coding systems apply critical product data, such as barcodes, batch numbers, and expiration dates, onto packaging surfaces. Integrated into the packaging line, these systems ensure consistent placement, regulatory compliance, and traceability from warehouse to end user.

Use Cases: Date coding for perishable goods, serialization for pharmaceuticals, barcode application for retail inventory systems

Industry Applications: Ubiquitous across all sectors — especially food, beverage, health care, and industrial manufacturing, where product information must be visible and scannable

Inspection Systems

Inspection systems leverage vision cameras, metal detectors, and X-ray units to identify packaging defects, contamination, or inconsistencies before products leave the facility. These machines serve as quality control checkpoints to catch non-conforming goods.

Use Cases: Catching labeling errors, damaged packaging, missing components, or foreign objects in products

Industry Applications: Critical in pharmaceuticals, food production, electronics, and automotive parts — industries with strict quality control and regulatory standards

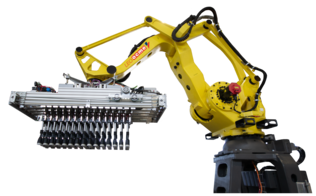

Robotic Pick and Place Systems

These systems use high-speed robotic arms to pick up products and place them into containers, onto conveyors, or into cartons in precise orientations. They offer programmable flexibility for a wide variety of shapes, sizes, and weights, making them a versatile addition to packaging lines.

Use Cases: Handling high-speed sorting or repetitive packaging tasks with minimal downtime and error

Industry Applications: Electronics, medical devices, personal care items, and bakery lines frequently use robotic systems to optimize placement and reduce manual handling

Conveying and Accumulation Systems

Conveying systems move products between machines, while accumulation systems buffer or store products temporarily to regulate flow. Together, they ensure seamless transitions between packaging stages and prevent bottlenecks that reduce line efficiency.

Use Cases: Buffer zones for inspection, rejection, or operator intervention; optimizing machine speeds across lines

Industry Applications: Found in nearly every automated line, particularly in bottling, canning, and cartoning operations where spacing, timing, and flow control are essential

Key Factors to Consider When Choosing End-of-Line Equipment for Packaging

Selecting the right machine requires more than just matching technical specs to product types. Consider these key factors to avoid performance bottlenecks:

Production Speed and Throughput

The capacity of the equipment should align with the facility’s current output while also accounting for future changes in order volume. Machines that operate below the required speed can cause production delays, while those built for significantly higher volumes may result in unnecessary capital expenses. The best solution offers a balance between present needs and the ability to scale over time.

Product Type and Packaging Format

The size, shape, weight, and fragility of the product will influence the selection of suitable equipment for packaging. Systems built for uniform, stackable items differ from those intended for fragile or irregularly shaped goods. It’s also important to consider how well the equipment handles the required packaging materials, such as cartons, trays, or shrink film, to ensure a cohesive and reliable packaging process.

Available Floor Space

A machine may meet operational specifications but still be unsuitable due to space constraints. Facilities with limited room may require compact or vertically oriented systems, while larger spaces can accommodate modular lines. Adequate clearance for maintenance, safety, and potential expansion should also be part of the layout assessment.

Level of Automation

The degree of automation should reflect both the technical capabilities of the facility and the availability of labor. Fully automated systems may be preferred in environments with minimal staffing or a need for high-speed throughput, whereas semi-automated machines offer greater flexibility for hands-on control. Integration costs and ongoing maintenance considerations will also influence the appropriate automation level.

Changeover Efficiency

For facilities managing multiple SKUs, fast and simple changeovers can make a significant difference in operational uptime. Equipment with user-friendly controls, tool-free adjustments, and programmable settings enables quicker transitions between product formats, which is especially valuable in short-run or seasonal production cycles.

Integration with Existing Equipment

Packaging machinery technology functions best as part of a coordinated line. Seamless integration with upstream and downstream systems is essential for maintaining workflow continuity. Mechanical compatibility, data communication, and synchronization with existing software platforms should all be confirmed before installation.

Make the Right Investment in End-of-Line Machinery with OCME USA

Selecting the right end-of-line machinery isn’t just about specifications — it’s about long-term value. The right system boosts efficiency, minimizes waste, and enhances overall output.

OCME USA offers a complete range of industrial packaging equipment engineered to meet the demands of modern production environments. Whether the priority is space efficiency, automation, or system integration, OCME delivers advanced packaging machinery and equipment designed for performance and reliability.

With deep industry experience and a commitment to responsive service, OCME USA helps manufacturers adapt to shifting requirements without compromising throughput or quality.

Explore our end-of-line solutions and connect with a specialist at OCME USA to find the right system for your facility.