Implementing an automatic case packing system is a strategic investment in operational excellence, designed to enhance efficiency, reduce labor dependency and elevate overall productivity. However, achieving a seamless transition is contingent upon meticulous planning, careful equipment selection and seamless installation.

This guide outlines step-by-step how you can achieve effective case packing system integration, highlighting key considerations such as floor space, system compatibility, production volume and the advantages of working with a trusted partner.

Step 1: Evaluate Your Current Production Environment

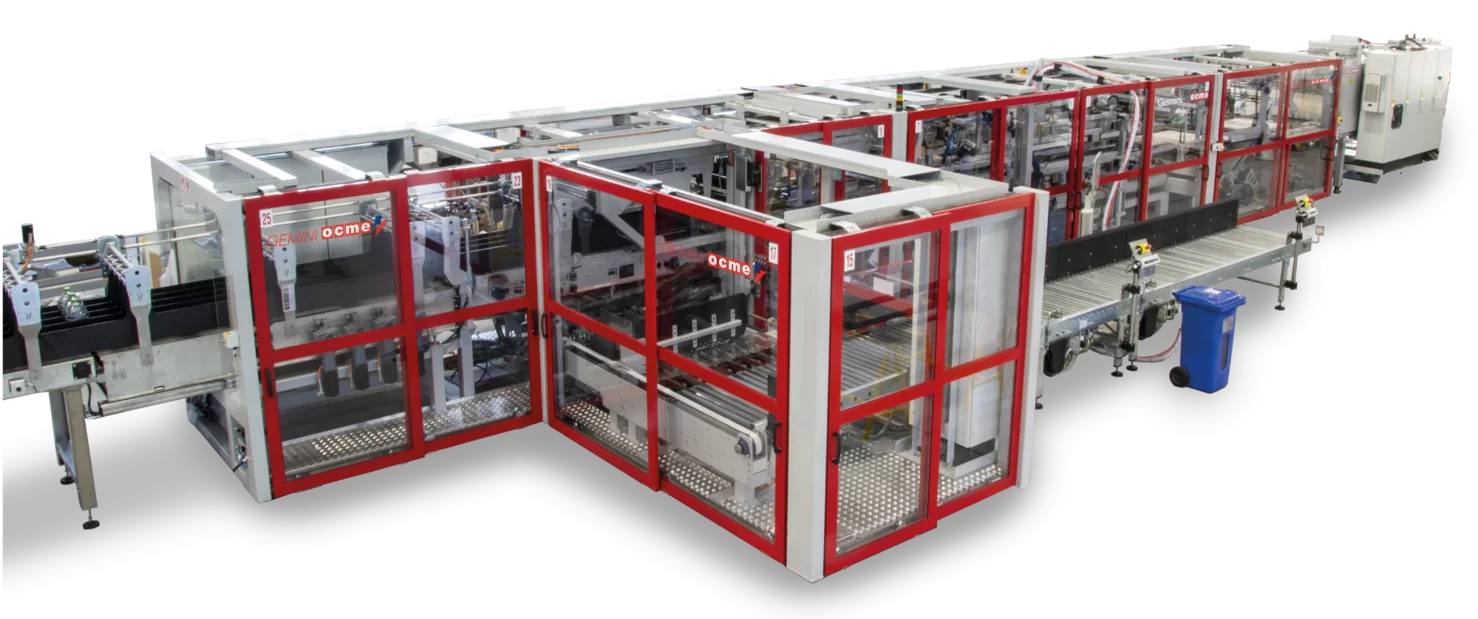

Begin by conducting a thorough evaluation of your existing production environment and assessing your available floor space. The footprint required for an automatic case packing system can vary significantly depending on the machine model and additional components such as conveyors and palletizers. Accurately measuring available space ensures your new system fits effortlessly into your current production layout.

Next, examine your production line’s current output and future projections. Consider questions like:

- How many cases per minute or hour do you need to achieve?

- Will future expansion or product changes impact your throughput?

- Do your current packaging processes align with your growth trajectory?

Understanding these factors clearly will guide your selection process toward the most suitable production line case packer.

Step 2: Identify Key Integration Requirements

Integration goes beyond mere physical installation; it involves ensuring compatibility across your entire production system. Consider the following aspects for a smooth case packing system integration:

Compatibility With Existing Equipment

Your new case packer must communicate effectively with existing machinery. Compatibility means not only mechanical alignment but also electronic communication with conveyors, sorting machines, palletizers,and labeling equipment. Choose systems known for their comprehensive integration capabilities to minimize downtime and avoid costly adjustments later.

Product Handling Flexibility

Analyze the nature of your products. Are they fragile, oddly shaped, or varying significantly in size? Different products require unique handling capabilities. Select an automatic case packing system that’s versatile enough to accommodate product variety without extensive adjustments or additional costs.

Automation Level and Operational Simplicity

Evaluate your team’s technical expertise and training requirements. The ideal system integrates effortlessly into your operation with minimal training, ensuring your team can swiftly adapt to new processes. Prioritize equipment featuring intuitive controls and user-friendly interfaces to maximize productivity from day one.

Step 3: Selecting the Right Automatic Case Packing System

Choosing the right equipment is arguably the most critical decision in the integration process. The system you select will directly influence your production efficiency, long-term return on investment and the overall overall operational effectiveness. A well-considered choice that aligns with both your immediate goals and long-term strategic vision ensures sustainable, scalable growth.

Types of Automatic Case Packers

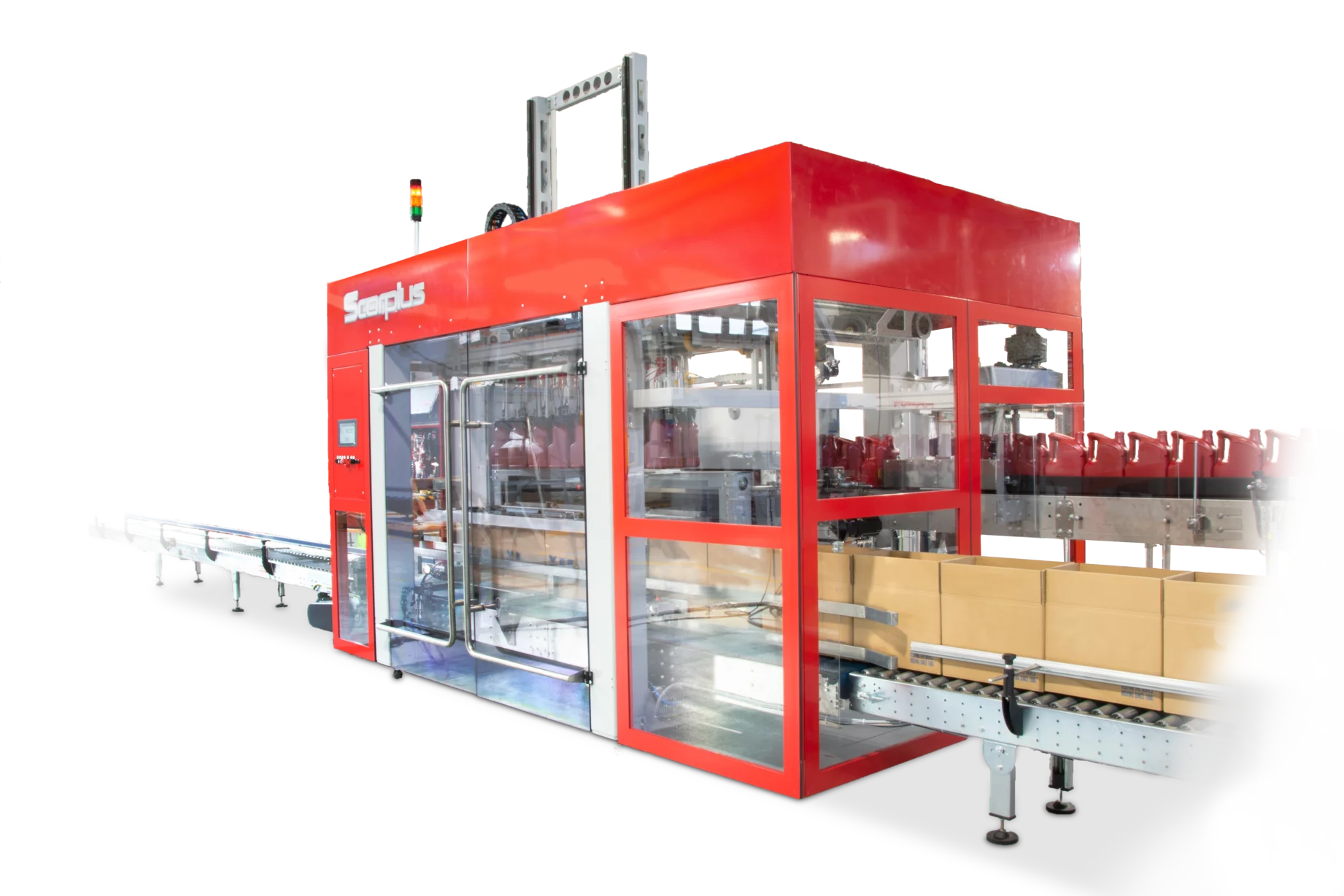

- Top Load Case Packers: Ideal for products that require gentle handling and precision placement.

- Side Load Case Packers: Optimal for high-speed packing and products easily handled from the side.

- Bottom Load Case Packers: Best suited for heavy or bulky items needing firm bottom support.

Each type addresses different needs, emphasizing the importance of understanding your specific production requirements before selection.

Evaluating Throughput and Production Volume

Match your case packer’s throughput capacity with your production demands. Overestimating your needs results in unnecessary costs while underestimating limits your ability to scale efficiently. OCME USA provides extensive consulting to match your throughput needs precisely, enabling sustainable growth and scalability.

Step 4: Planning the Installation Process

Proper planning significantly impacts the ease and success of your installation. The complexity of case packing system integration necessitates detailed coordination with internal teams and external suppliers.

Preparation of Installation Area

Clear, level and prepare your designated installation area well ahead of the scheduled installation date. Ensure utilities like electricity, compressed air and network connectivity are easily accessible. Proper infrastructure preparation minimizes unexpected delays during the installation.

Defining Project Timelines and Milestones

Define clear deadlines for each stage, from delivery and installation to initial testing and final commissioning. Sharing these milestones with your internal teams and external providers ensures coordinated efforts and smooth progress throughout the installation phase.

Step 5: How to Install the Case Packing Machine: Execution and Testing

Once your preparation is complete, it’s time to physically install your chosen equipment.

Here’s a concise breakdown of this process:

1. Equipment Installation

Professional installation typically includes mechanical assembly, electrical wiring and pneumatic connections. Though some facilities may opt for internal teams, choosing experienced technicians, particularly from equipment suppliers like OCME USA, ensures precise assembly and reduces the risk of errors.

2. Integration and System Programming

Integration involves connecting your new automatic case packing system to existing production line components. Technicians program the equipment, configure control systems and perform initial synchronization with existing machines to guarantee seamless operation.

3. Thorough Testing and Optimization

After installation, rigorously test your case packer under realistic production conditions. Conduct comprehensive operational checks to ensure the system consistently meets your production standards. Address any issues promptly to ensure optimized performance and reliability.

Step 6: Training and Operational Transition

Effective training plays a critical role in achieving full operational capacity swiftly and sustainably. Comprehensive training covers equipment operation, basic troubleshooting, routine maintenance and safety protocols.

Partnering with a provider like OCME USA provides access to extensive training and ongoing support, enhancing your team’s confidence and proficiency in managing your new equipment effectively.

Advantages of Working With an Experienced Provider

Choosing an experienced provider for your automatic case packing system can significantly impact the overall success of your integration process. Partnering with industry professionals with a proven track record in end-of-line automation ensures your integration is efficient, cost-effective, and aligned with your operational goals.

Here are several key advantages to consider:

Deep Industry Knowledge and Tailored Solutions

An experienced provider brings extensive knowledge of the complexities involved in case packing system integration. They understand how various types of machinery perform across different manufacturing environments and industries. Leveraging their expertise, you can identify solutions tailored specifically to your operational needs, ensuring compatibility with your existing equipment and processes.

Comprehensive Technical Support and Service

Reliable technical support is vital to maximizing productivity and minimizing downtime. Providers with robust technical capabilities offer comprehensive maintenance programs, proactive system monitoring and prompt troubleshooting support. Quickly addressing any issues or disruptions ensures your automatic case packing system consistently performs at peak efficiency.

Effective Project Management and Installation Guidance

A seasoned provider offers detailed project management services, assisting with site preparation, logistical coordination, equipment installation and commissioning. Their proficient teams help you navigate common integration challenges, reducing the risk of delays or costly mistakes.

Clear timelines, effective communication and structured implementation practices simplify the process, enabling your new equipment to quickly become operational.

Scalability and Flexibility for Future Growth

Choosing a well-established provider ensures that your chosen production line case packer can adapt as your production needs evolve. Experienced providers design solutions that anticipate changes in product types, volumes and packaging formats, allowing your equipment to scale seamlessly. This flexibility extends the life and value of your investment, keeping your operation agile and competitive.

Enhanced Training and Operational Readiness

Professional providers include comprehensive training programs that thoroughly prepare your team for system operation and maintenance. Their expertise ensures your staff quickly gains proficiency in running and maintaining your new machinery, enhancing safety, efficiency and productivity from the outset.

By partnering with an experienced provider for your end-of-line automation, you gain access to resources, expertise and strategic insights for successfully integrating an automatic case packing system into your production line.

Key Takeaways for Successful Integration

Integrating an automatic case packing system into your production line can dramatically enhance your manufacturing efficiency and profitability. Remember these critical points to ensure successful integration:

- Clearly define your production requirements and space constraints.

- Choose compatible and flexible equipment tailored to your operational needs.

- Prioritize thorough preparation, testing and training to smooth the transition.

- Partner with experienced providers like OCME USA to maximize your investment.

By following these guidelines, you’ll optimize your end-of-line automation, streamline your operations, and position your company for sustained growth and competitive advantage.

Integrate Your Automatic Case Packing System Seamlessly With OCME USA

Integrating an automatic case packing system into your production line is a strategic decision that boosts efficiency, profitability, and competitiveness. Whether you’re aiming to streamline your packaging operations or complement existing equipment like a stretch wrapper, successful integration demands thoughtful planning, precise execution, and ongoing support.

OCME USA excels in delivering comprehensive packaging solutions, including advanced robotic systems and customized case packing system integration. Our experts assist you through every phase, from evaluating floor space and compatibility to providing robust training and maintenance support.

With OCME’s industry-leading expertise, your new production line case packer and integrated automation technologies will perform reliably and efficiently from installation onwards. Contact us today to learn more about installing a case packing machine effectively and achieving optimal operational performance.