Modern supply chains are becoming increasingly intricate. With globalization, shifting consumer preferences and rising e-commerce volumes, the complexity of logistics and fulfillment operations is at an all-time high. In light of these growing complexities, businesses face mounting pressure to enhance their packaging processes to meet customer expectations.

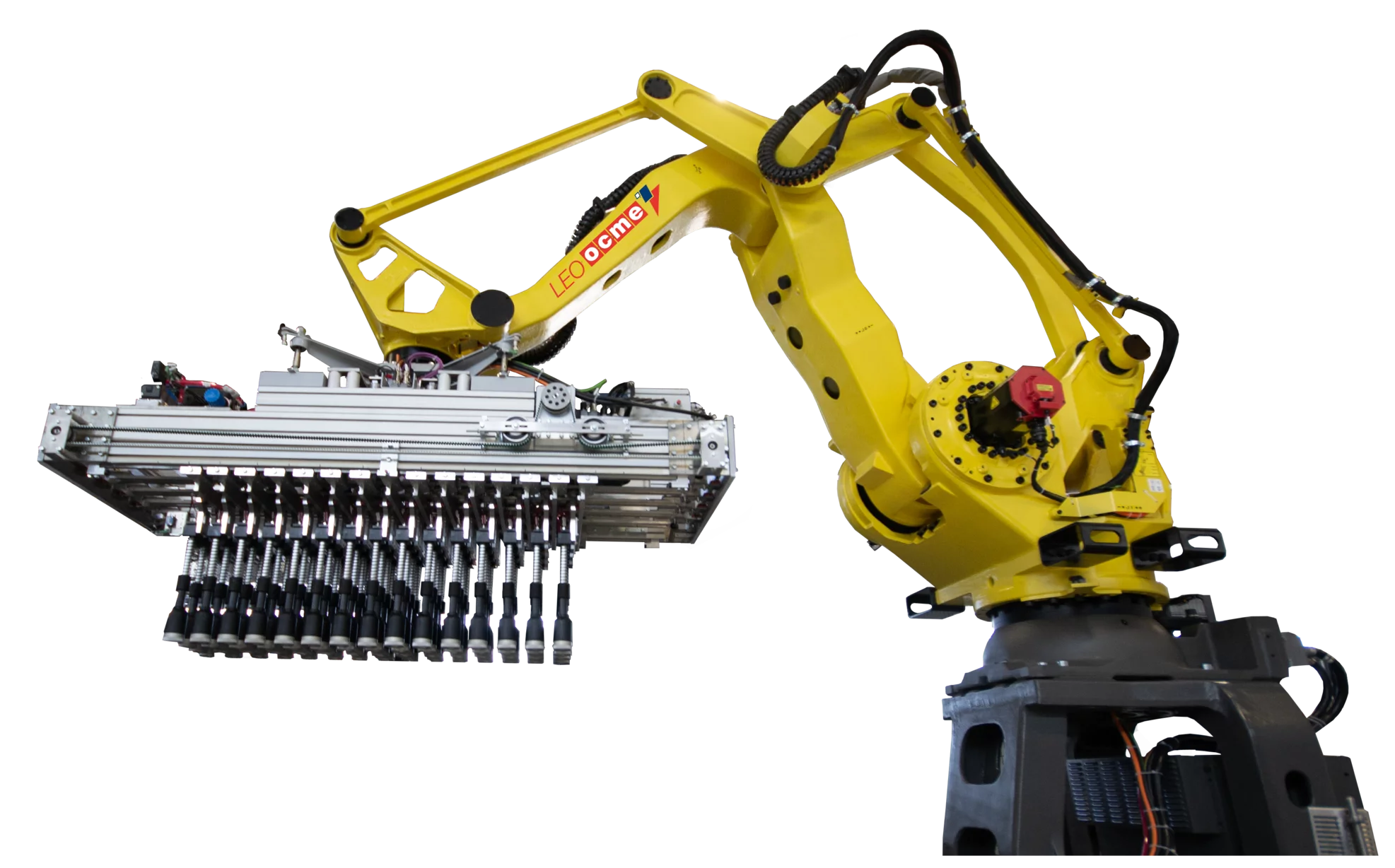

To navigate these complexities and maintain competitiveness, businesses are increasingly adopting advanced technologies like robotics in supply chain management to automate critical operations such as packaging, sorting and palletizing. These robotic solutions offer precise and efficient execution of repetitive or labor-intensive tasks, enabling companies to simplify intricate supply chain processes while delivering consistent, high-quality outcomes

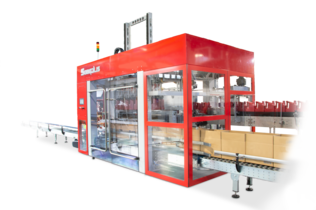

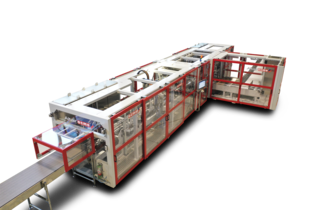

Automated case packing machines are among the most impactful advancements in robotics-driven supply chain automation. These sophisticated systems help optimize the final stages of production, assisting companies to manage the increasing demands of modern supply chains with greater speed and reliability.

In this article, we’ll explore in greater detail how automated case packing machines contribute to efficiency, productivity and sustainability across today’s evolving supply chain environments.

How Automated Case Packing Machines Work

Automated case packing machines handle the final stage of the packaging process, placing products into shipping cases with speed, consistency and precision. These systems combine robotic arms, vision sensors, conveyors and software to automate tasks that would otherwise require multiple operators.

Depending on the application, automated case packers can:

- Erect and position cases

- Orient and load products into specific configurations

- Seal and label finished boxes

- Route packages for palletizing or shipping

Types of Automated Case Packing Systems

Automated case packing systems come in various types, each designed to handle specific product shapes, sizes and packing requirements. Here are the types of systems most commonly used:

Top-Load Case Packers: This is ideal for delicate or irregularly shaped products.

Side-Load Case Packers: These are suited for stable items that can slide easily into cartons.

Wraparound Case Packers: This is used for tight, secure packaging with minimal material waste.

These machines are often engineered or configured to match specific industry needs, product dimensions and production speeds.

What Is Driving the Adoption of Automated Case Packing in Modern Supply Chains?

What’s driving the adoption of automated case packing isn’t just the technical capability but the increasing urgency for operational resilience and adaptability. Businesses today are facing:

- Labor shortages that make it difficult to staff repetitive manual tasks.

- Escalating operational costs across labor, materials and energy.

- Higher demand for customized packaging and faster fulfillment.

- Increased complexity from managing multi-SKU or short-run production lines.

Automated case packers offer a direct response to these challenges by streamlining throughput and minimizing variability without requiring expanded footprints or additional workforce. They also integrate easily with upstream equipment and downstream logistics systems, helping businesses stay agile while maintaining consistent output.

Key Benefits of Automated Case Packing Machines in Modern Supply Chains

Today’s supply chain managers seek streamlined, efficient processes capable of adapting quickly to market demands. Below, we’ll examine specific areas where automated case packing machines significantly enhance operational efficiency and effectiveness.

Eliminating Bottlenecks and Increasing Efficiency

Packaging bottlenecks can drastically reduce supply chain efficiency and throughput. Implementing robotics in logistics through automated case packing machines eliminates these bottlenecks, streamlining workflows and maintaining consistent product flow.

Continuous automated operation reduces downtime and enhances productivity, allowing companies to meet tight production schedules and improve delivery performance.

Accelerating Supply Chain Velocity With Automation

The rapid movement of goods through supply chains is a cornerstone of operational success. Automated case packing machines accelerate this process, enabling faster and more accurate packing than manual labor can achieve.

The result is shorter order fulfillment cycles, improved responsiveness to market fluctuations and heightened overall logistics efficiency, which are vital attributes for companies leveraging robotics in logistics to maintain competitive positioning.

Reducing Labor Costs and Errors

Manual packaging is labor-intensive, costly and prone to human error. Mistakes such as mislabeling or incorrect product counts translate directly into financial losses and customer dissatisfaction.

Incorporating robotics supply chain solutions dramatically reduces these risks. By automating repetitive tasks, companies reduce dependence on manual labor, lower training costs and minimize packaging error rates, significantly boosting profitability and service quality.

Enhancing Product Protection and Consistency

Protecting products throughout transit is crucial, especially for fragile or perishable goods. Automated case packers deliver consistent packing quality, ensuring optimal placement and minimizing potential damage during shipment.

Precision packaging using robotics ensures secure seals, proper cushioning and uniform packing methods. This consistency reduces returns and damaged products, enhances customer satisfaction and protects brand reputation.

Sustainability Through Automated Packing Solutions

Sustainability continues to rise in importance due to consumer preference, regulatory requirements and corporate social responsibility goals. Automated case packing solutions directly support sustainability objectives by optimizing packaging materials usage and energy efficiency.

Machines precisely control the quantities of packaging material, significantly reducing waste. In addition, automated case packers typically operate with less energy, supporting broader sustainability and cost-saving initiatives.

Supporting Regulatory Compliance

Industries like pharmaceuticals and food production face stringent and continuously evolving regulations for packaging safety and labeling. Automated packing systems can rapidly adapt to changing regulations through straightforward software recalibrations or configuration adjustments, significantly reducing compliance-related operational disruptions and associated costs.

Improving Workplace Safety and Ergonomics

Automating physically demanding tasks reduces workplace injuries, significantly improving employee safety and comfort. By delegating repetitive, strenuous tasks to robotics, companies can provide safer, more ergonomic working environments, improving employee retention and workplace satisfaction.

Leveraging Data Insights for Continuous Improvement

Robotic packing systems gather valuable real-time data on packing efficiency, throughput, error rates and material use. These analytics help businesses swiftly identify inefficiencies, troubleshoot issues proactively and optimize packing processes continually.

With data-driven improvements, companies can consistently refine their supply chain strategies, making smarter, quicker operational decisions that enhance their overall competitiveness.

Selecting the Right Automated Packing Solution for Your Business

Finding the right automated packing solution involves considering your unique operational needs and growth plans. Here are key considerations to guide your decision-making process:

Understand Your Product’s Needs

Different products require tailored packaging solutions. Consider the following examples:

- Fragile products, like electronics and glass, benefit from robotic systems designed for gentle, precision handling to avoid damage.

- Temperature-sensitive items, such as perishable foods or medications, require high-speed automated packers that maintain product integrity and freshness.

- Companies with a diverse product range should invest in modular robotic packing systems that can quickly adapt to different sizes, packaging types or materials.

Match Your Production Volume and Demand Patterns

Assess your facility’s typical output and seasonal demand changes:

- High-volume facilities need fully automated, robust systems with continuous robotic operations that maintain high throughput without disruptions.

- Medium-volume operations often thrive with semi-automated systems that combine human oversight and robotic accuracy, providing optimal flexibility at reasonable costs.

- Facilities experiencing seasonal demand spikes benefit from modular systems that can scale up or down quickly without significant downtime or extra investment.

Optimize Facility Space

Since factory and warehouse spaces are typically limited, look for robotic packing equipment that conserves and maximizes available space.

Compact solutions, including vertically designed machines or multifunctional robotic units, effectively manage space constraints and support future expansion.

Also, ensure equipment offers ergonomic accessibility for easy maintenance, keeping productivity high without sacrificing valuable floor area.

Ensure Easy Integration With Existing Systems

Integrating new robotic packing equipment should enhance, not complicate, existing operations.

Prioritize solutions compatible with current Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) and logistics platforms.

Machines designed for smooth integration minimize disruptions, streamline data flows and improve overall operational efficiency.

Industries That Benefit From a Robotics Supply Chain

Automated case packing machines and robotics in supply chain management offer advantages across numerous industries. Below are five prominent sectors benefiting significantly from these technologies:

Food and Beverage

This industry demands speed, hygiene and accuracy. Robotic case packers reduce human contact with products, improve packaging consistency and simplify regulatory compliance, which is critical for handling perishable foods safely.

Pharmaceuticals and Healthcare

Automated packing ensures precise packaging, accurate labeling and full regulatory compliance, which is essential for maintaining consumer trust and product integrity in the pharmaceutical and medical industries.

E-commerce and Retail Distribution

In an era of rapid online growth, automated case packing streamlines logistics, shortens fulfillment cycles, reduces packaging errors and significantly enhances customer satisfaction.

Electronics Manufacturing

Electronic products need careful, consistent packaging to prevent damage. Robotics ensures delicate components receive precise handling, reliable packaging and timely deliveries, protecting product quality and brand reputation.

Consumer Packaged Goods

Consumer Packaged Goods (CPG) companies benefit from automated packing’s speed, consistency and scalability. It supports high-volume production without compromising quality or consumer appeal.

Simplify Your Supply Chain With OCME USA

As the demands of modern supply chains continue to grow, selecting the right automated case packing machine — and the right partner to provide it — can make a significant difference. Effective solutions go beyond machinery. They offer seamless integration, expert support and scalability to match your business’s long-term goals.

OCME USA delivers advanced end-of-line packaging systems engineered to meet the real-world demands of modern manufacturers and distributors. With a comprehensive portfolio of automated case packing solutions and a team of engineering specialists, OCME USA helps companies across industries reduce complexity, boost efficiency and future-proof their packaging operations.

Contact OCME USA today to explore the right automated case packing solution for your business.