Optimizing production is essential for any manufacturing operation. While every phase of production is indispensable, end-of-line automation is especially important for ensuring products are ready for the next part of the supply chain. However, the challenge lies in balancing operational efficiency with secure product packaging to avoid damage during transport.

Modern factory operations rely on case packing machines as a key innovation to maximize performance, reliability and return on investment (ROI). If you are interested in understanding the answers to: what is a case packing machine, what are the benefits of case packing machines and how can they improve your operations, this guide covers everything you need to know to achieve higher performance and long-term success.

What Is a Case Packing Machine?

A case packing machine automates the process of placing finished products into cartons, trays or shrink-wrapped packages. Positioned at the end of the production line, these machines ensure your manufactured goods are efficiently packaged and ready for palletizing, shipment, and distribution.

By replacing manual labor with precision-engineered automation, case packing machines enhance end-of-line efficiency, reduce errors, and improve throughput. They help eliminate common challenges such as inconsistent packing, slow cycle times, and quality fluctuations.

Case packing machines are becoming a standard feature in manufacturing operations, especially for products such as beverages, food, personal care and industrial goods. By automating this process, manufacturers can achieve consistent packaging quality while maintaining the productive pace required to meet growing market demands.

Types of Case Packing Machines

Manufacturing facilities can improve production with case packing machines. However, the type they need can depend on factors like their product, packaging format and production objectives. Some case packing automation solutions can include:

Shrink Wrappers

Key Features:

- High-speed bundling capability

- Versatile for various product shapes and sizes

- Compact footprint for space-saving installations

Shrink wrappers bundle products together using heat-sensitive film that shrinks tightly around them. The products pass through a heat tunnel, where the film contracts and secures them firmly. This method ensures product stability during transit and offers protection against dust, moisture and tampering during shipping.

Wrap Around Case Packers

Key Features:

- Enhanced packaging strength

- Reduced carton material usage

- High adaptability to different case sizes

Wrap around case packers form a carton case around the product rather than the less efficient practice of loading products manually into a pre-formed box. The machine wraps the products tightly in a single, continuous motion. This method improves packaging strength and often results in material savings. It’s ideal for high-volume operations seeking maximum packaging efficiency.

Combination Packers

Key Features:

- Multi-format packaging flexibility

- Rapid changeover capabilities

- Integration with upstream and downstream equipment

Combination packers offer flexibility by performing multiple packing styles within a single machine. This is suitable for manufacturers handling different products requiring different packing solutions, such as shrink wrapping, tray packing or case packing. Combination machines provide a versatile solution tailored to dynamic production requirements without investing in multiple systems.

Tray & Lid

Key Features:

- Secure product containment

- Excellent product presentation

- Suitable for various tray and lid dimensions

Tray and lid packers place products into a tray and then seal them with a protective lid. This method offers excellent product visibility. It is commonly used for consumer goods requiring strong merchandising appeal while ensuring secure handling.

Horizontal Shrink Bundlers

Key Features:

- Heavy-duty construction

- High load-bearing capability

- Optimized for high-speed production

Designed for heavy or bulky products, horizontal shrink bundlers provide reinforced bundling that can withstand rugged shipping and storage environments. They can securely package heavy or large items by applying shrink film horizontally around product groups. These machines are often deployed in industries with high-stress production, such as beverage, building materials and automotive supplies.

Shrink Bundlers and Horizontal Baggers

Key Features:

- Minimal material consumption

- Ideal for bulk or irregularly shaped items

- Streamlined maintenance and operation

Shrink bundlers and horizontal baggers group products together with minimal secondary packaging. They apply a shrink film around products horizontally, then seal and shrink-wrap them, optimizing material usage and offering flexibility. They are particularly useful for irregularly shaped products that cannot fit in a regular box or when secondary packaging needs to be minimized.

5 Benefits of Case Packing Machines

Manufacturing operations constantly strive for efficiency. As demand increases for your product, it’s imperative that you improve production with case packing, as it is the final step before palletizing your products and having them shipped. While securing your goods is important so that they reach your partners or clients in good condition, your operations shouldn’t compromise on efficiency.

By investing in case packing automation, your operations can see measurable improvements in production. Here are five benefits of case packing machines:

1. Higher Production Efficiency

After your products are manufactured, manually packing them into end-of-line packaging can cause production bottlenecks. Automated case packing systems can dramatically reduce inefficiencies at the end of the production line.

Machines can operate continuously at high speeds while producing consistent quality. This ensures that higher output targets can be met or exceeded without compromising how secure your goods are for transport. The efficiency also helps your business avoid the risk of bottlenecks. This is particularly helpful if production needs to scale during seasonal demand or if your business plans require increased production output.

Manufacturers experience faster cycle times and smoother transitions between product runs. This enables facilities to meet larger order volumes, reduce lead times and better adapt to fluctuating market demands. As a result, your operations can experience faster time-to-market, improved responsiveness to market demands and a stronger competitive edge.

2. Improved Product Protection

Poorly packaged products risk damage during handling, transportation and storage. This can result in revenue losses and impact your bottom line. Manual packaging has risks of inconsistent output and inefficient practices.

Proper case packing significantly reduces product damage throughout the next steps of the supply chain. Automated systems ensure each product is securely placed and packaged, minimizing the risks of crushing, breakage or contamination.

With precise, secure packaging, manufacturers can reduce losses caused by returns, replacements and customer dissatisfaction. This protects the product’s integrity and your brand's reputation, in addition to your bottom line.

3. Reduced Labor Costs

Manual packing is labor-intensive, inconsistent and prone to human error. While machines require a higher upfront investment, your operations can improve production with case packing automation systems tailored to your existing process. With the right machine, you can experience a positive ROI with consistent packing and minimal operational costs.

By investing in case packing machines, manufacturers reduce dependence on manual labor and lower operational costs. This also creates a safer, more ergonomic work environment, as employees will no longer handle lifting heavy loads. These labor resources can then be reallocated to higher-value activities, such as quality assurance, process optimization and customer service, leading to overall operational gains.

4. Enhanced Consistency and Quality Control

Automated systems monitor and control critical variables such as alignment, sealing and labeling, ensuring every package meets strict quality criteria. By automating your end-of-line packaging, you can ensure that every package is handled identically, minimizing variation and elevating overall packaging quality.

Achieving consistency is crucial for brand image, as it impacts how buyers perceive your brand and the quality of your products. Additionally, compliance with regulatory standards and retailer requirements may also be necessary.

5. Optimized Use of Materials

Modern case packing machines are designed with material optimization in mind. While manual packing has a risk of errors that can lead to wasted resources, machines can precisely control material use.

These systems minimize material waste and maximize resource utilization by leveraging technology to handle film tension, carton dimensions and shrink ratios. This results in significant cost savings and supports corporate sustainability initiatives by reducing the carbon footprint associated with packaging operations.

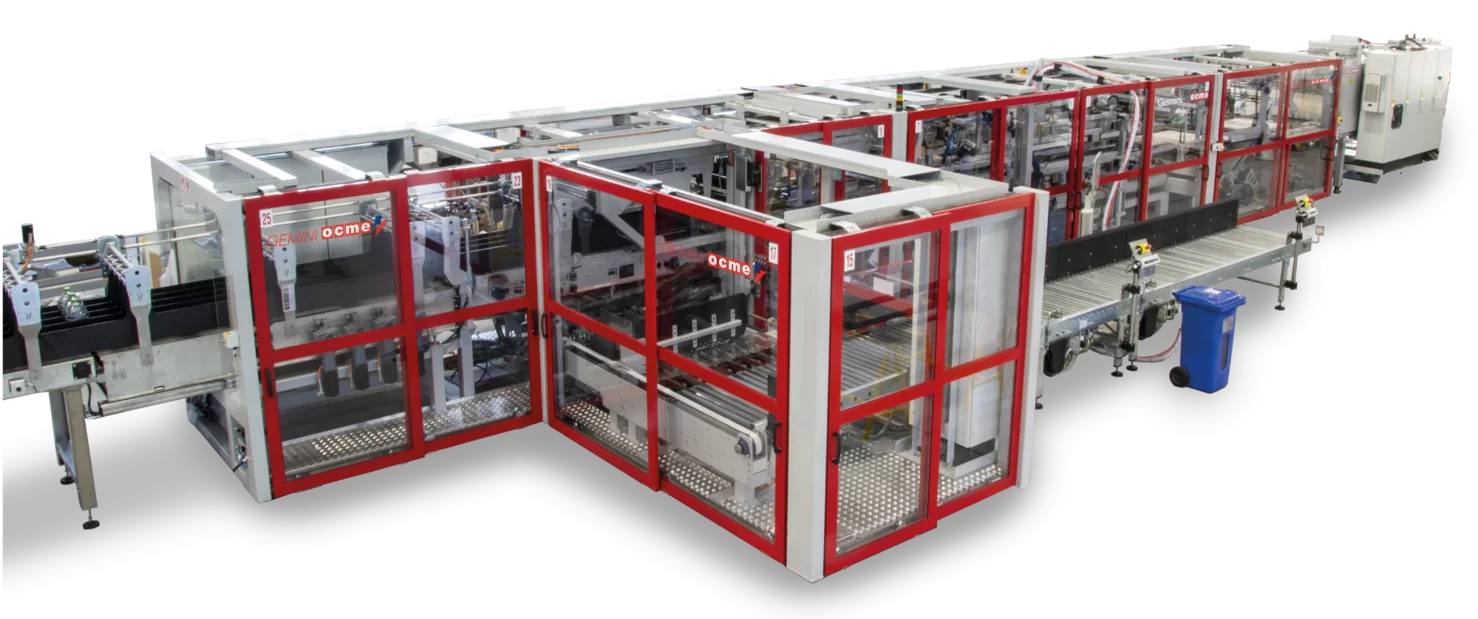

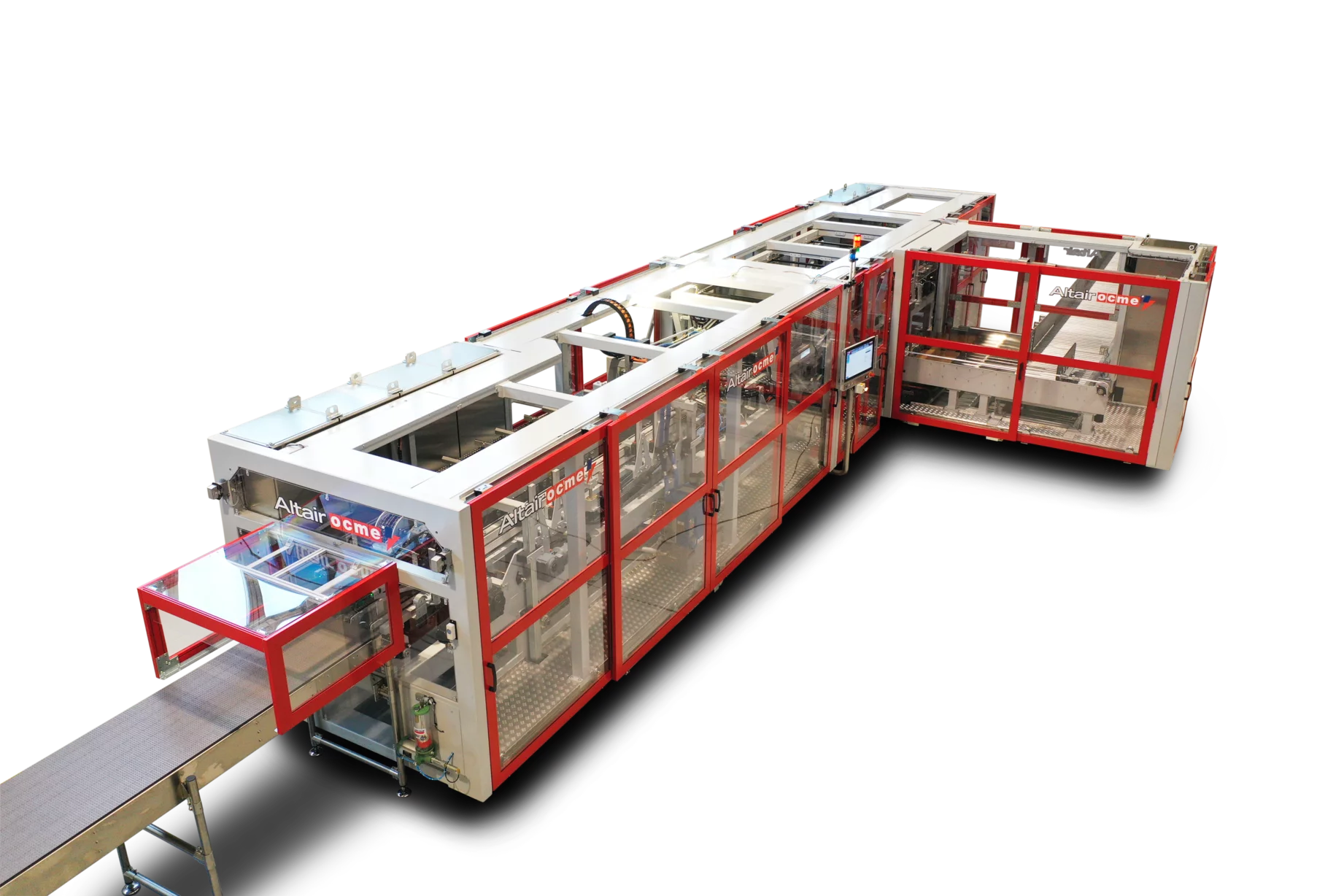

Why Choose Case Packing Machines From OCME USA

OCME USA stands at the forefront of end-of-line innovation. With decades of experience and a relentless focus on performance, reliability and ROI, we have earned the trust of leading brands worldwide.

Our case packing solutions are engineered to be flexible, customizable and scalable for any manufacturing operation. Whether you need a high-speed shrink wrapper or a multi-functional combination packer, we tailor each system to your specific operational requirements. Our emphasis on modular designs, energy efficiency and intuitive controls ensures that your investment delivers immediate and long-term value.

Beyond our reliable equipment, OCME USA is a strategic partner committed to our customers' success. We provide full lifecycle support from consultation and installation to training, maintenance and upgrades. This ensures optimal uptime and continuous improvement.

By choosing OCME USA, you gain access to a trusted ally dedicated to enhancing your production capabilities, protecting your products and maximizing your ROI through cutting-edge technology and world-class service.

Improve Your Operations With OCME USA

Investing in case packing machines is a strategic move that enhances throughput, quality and profitability. In a competitive market, the right end-of-line solution is key to staying ahead.

Elevate your packaging operations with OCME USA. Contact us today to request a quote or get more information about our innovative case packing solutions.