Rising demand, tighter delivery schedules, and an increasing number of SKUs have made manual packaging processes harder to sustain. In fast-moving production environments, even small inefficiencies at the end of the line can ripple upstream, slowing throughput, increasing labor costs, and compromising packaging quality. As production expectations rise and floor space becomes more valuable, many facilities are reevaluating how products are packed for shipping and distribution.

This is where automated packing solutions make a difference. Designed to streamline secondary packaging, case packing machines help manufacturers keep up with demand while reducing labor reliance and improving consistency. Whether loading cartons, bottles, pouches, or trays into cases, these systems handle repetitive tasks with precision and speed, making them a reliable part of modern packaging operations.

In this post, we’ll take a closer look at what case packing machines are, the different types available, and how to choose the right system based on your production goals.

What Is a Case Packing Machine?

A case packing machine is an industrial packaging solution designed to load products into corrugated boxes (also called cases or cartons) for shipping and distribution. These machines handle multiple tasks, including collating, orienting, grouping, and inserting individual products or multi-packs into pre-formed cases.

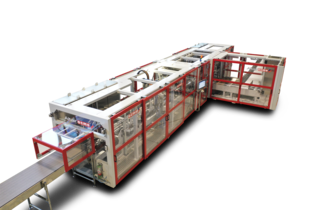

In most modern facilities, automatic case packing machines integrate seamlessly into broader packaging lines, often sitting downstream of primary packaging systems like flow wrappers, thermoformers, or bottling machines. Their goal is to automate and standardize what was once a labor-intensive process, reducing manual touchpoints and improving both speed and accuracy.

Why Case Packing Machines Are Essential to End-of-Line Automation

As packaging lines grow more sophisticated, manual packing processes can quickly become bottlenecks. Case packing machines eliminate this risk by:

- Increasing throughput with continuous or intermittent motion automation

- Reducing product damage through precision handling and orientation

- Enhancing workplace safety by reducing repetitive strain and physical labor

- Ensuring consistency with repeatable, standardized case loading

- Supporting downstream palletizing with correctly formed and loaded cases

For facilities dealing with SKU proliferation or mixed-product packaging, modern automatic case packing solutions also offer rapid changeovers, recipe control, and advanced vision systems to verify accuracy at high speeds.

Types of Case Packing Machines

Not all case packing applications are the same. Product characteristics, orientation, fragility, line speed, and pack pattern all influence the selection of a suitable case packing solution. Below are the most common types of case packaging machines used across industrial sectors.

Top-Load Case Packers

Top-load case packers insert products vertically into open-top cases. This format is well-suited for lightweight, delicate items or requiring upright orientation, such as bottles, cartons, or flexible pouches.

Best For: Bottled beverages, cosmetics, personal care products

Advantages: Gentle handling, compact footprint, flexibility in pack patterns

Variants: Robotic pick-and-place, gantry-style, delta robots

Side-Load Case Packers

Side-load case packers push or slide products horizontally into cases. This method is ideal for items already pre-collated items or flat-packed products, such as shrink-wrapped packs, trays, or cartons.

Best For: Canned goods, boxed food, pharmaceutical cartons

Advantages: High-speed operation, suitable for rigid packaging

Variants: Continuous motion, intermittent motion, servo-driven loaders

Wrap-Around Case Packers

Wrap-around packers form, load, and seal corrugated blanks around products in one continuous process. Unlike traditional regular slotted container (RSC) styles, wrap-around cases use less material and create tighter, more stable packaging.

Best For: Multi-packs, cans, jars, bricks

Advantages: Material efficiency, superior load containment, ideal for retail-ready packaging

Integration: Often combined with automatic gluing and sealing systems

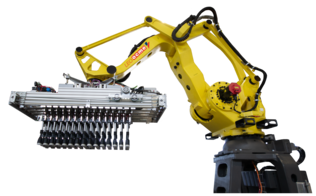

Robotic Case Packers

Robotic case packers use articulated arms or delta robots to pick and place products into cases with advanced motion control and vision guidance. These systems are highly flexible and programmable, allowing for fast product or pattern changeovers.

Best For: High-mix production, fragile or irregularly shaped products

Advantages: Multi-SKU handling, rapid changeovers, space-saving configurations

Key Components of a Case Packing System

The design of case packing machinery can vary depending on product type, speed requirements, and automation level. However, most systems share key functional components that work together for efficient, precise case loading.

Product Infeed Conveyor

This component introduces products into the system in a controlled and consistent manner. It may include guides or sensors to align items properly before grouping. Smooth, reliable product flow is essential for maintaining line efficiency.

Collation System

The collation unit arranges incoming products into a specific configuration, such as a 3x4 or 2x6 pattern, before loading them into a case. It ensures that products are grouped accurately and consistently based on pre-programmed formats.

Case Erector or Magazine Feeder

This unit either erects flat case blanks into open boxes or feeds pre-formed cases into the loading zone. For operations using wrap-around cases, the magazine supplies flat blanks folded around the product during the packing process.

Product Loading Module

At the heart of the system, this module loads products into the case using mechanical pushers, pneumatic actuators, or robotic arms. The choice of loading technology depends on product fragility, orientation, and speed requirements.

Case Sealing Unit

Once the case is filled, it is sealed using tape, hot melt glue, or other closure methods. Proper sealing ensures structural integrity during transport and storage.

Discharge Conveyor

The sealed case is transferred to the next stage, typically a palletizer or accumulation zone. Discharge conveyors often include sensors for quality control or downstream signaling.

In automatic case packing machines, these components are orchestrated by programmable logic controllers (PLCs) and driven by servo motors to deliver high-speed, synchronized performance with minimal manual intervention.

Where Case Packing Machines Are Used

Case packaging machines are ubiquitous in facilities where consistent, high-throughput secondary packaging is a priority. Some of the industries that rely most heavily on automatic case packing include:

Food & Beverage

The food and beverage industry operates under strict hygiene regulations and often deals with perishable or fragile products moving at high speeds. Packaging must not only be efficient but also preserve product integrity and meet sanitation standards.

Case packing systems in this sector are used to handle:

Bottled water, soda, beer, juice

Canned soups, vegetables, sauces

Ready-to-eat meals, frozen foods, snacks

These applications often require washdown-rated case packing machinery, precise orientation control, and quick changeover capabilities to accommodate frequent SKU shifts.

Consumer Packaged Goods (CPG)

Consumer packaged goods encompass a broad range of items sold through retail channels, often in high volumes and with strong visual branding requirements. Packaging consistency and shelf-readiness are key priorities.

Automatic case packing machines are commonly used for:

- Personal care items (shampoo, soap, lotion)

- Household products (detergents, cleaning sprays)

- Pet food, beauty products

These lines often require adaptable systems that can handle different container types and packaging formats while maintaining product alignment and brand presentation in the final case.

Pharmaceuticals & Healthcare

Pharmaceutical and healthcare packaging demands a high level of precision, traceability, and compliance with regulatory standards. Products are often sensitive or fragile, requiring careful handling during case packing.

Common applications for case packing in this industry include:

Blister packs, vials, diagnostic kits

Medical devices, supplements, over-the-counter medications

Vision-guided robotic packers and serialization-enabled equipment are often used to maintain validation integrity, ensure traceability, and reduce the risk of product damage or mix-ups.

Industrial & Automotive

The industrial and automotive sectors deal with durable goods and components that must be packaged securely for transport, often in mixed sizes and weights. Efficiency, system integration, and traceability are key requirements.

Case packing systems in these operations handle:

- Bearings, small parts kits, chemical containers

- Tools, electronics, and subassemblies

These lines often integrate case packing machinery with warehouse management or ERP systems, supporting real-time inventory updates and minimizing manual repacking or handling during order fulfillment.

What to Consider When Choosing a Case Packing Machine

Investing in case packing machinery is not a one-size-fits-all decision. To select the right machine for your production line, consider the following:

- Product Type: Size, shape, fragility, and packaging format

- Throughput Requirements: Cases per minute needed to match upstream equipment

- Footprint: Available floor space and layout constraints

- Changeover Needs: Frequency of SKU changes and downtime implications

- Integration Requirements: Compatibility with case erectors, conveyors, vision systems, and palletizers

- Sanitary Design: For food, beverage, and pharmaceutical operations

- Total Cost of Ownership: Consider maintenance, training, and energy consumption, not just purchase price

Working with a supplier that offers customizable solutions, technical support, and a strong service network can significantly improve the long-term value of your automatic case packing machine investment.

The Role of Automation in Case Packing Efficiency

The move toward automatic case packing is part of a larger trend in smart manufacturing. These systems now feature:

Advanced HMI Interfaces for recipe management and diagnostics

Remote Monitoring and IIoT integration

Predictive Maintenance Alerts to reduce unplanned downtime

Vision Systems for real-time quality control and error detection

Optimize Your Case Packing Operations With OCME USA

As production lines demand more speed, product variety, and automation, case packing machines have become central to maintaining efficiency and throughput. From side-load systems to robotic and wrap-around technologies, modern case packaging machines are built to deliver reliable performance at scale.

OCME USA offers engineered case packing solutions built for long-term success. With a full range of top-load, side-load, robotic, and wrap-around systems, our equipment is designed to integrate seamlessly into your end-of-line environment, enhancing performance, minimizing downtime, and adapting as your production needs evolve.

Explore our full range of case packing machines and connect with our team to find the best fit for your operation.