Installing an OCME USA secondary packaging or logistics line is far more than placing equipment on the production floor. It’s a tightly coordinated project that starts with engineering drawings and utility assessments, progresses through sequenced deliveries and laser-guided machine alignment, and extends well beyond start-up with hands-on training, remote diagnostics, and comprehensive lifecycle service plans.

Each phase of a well-executed packaging line design by OCME USA specialists focuses on accelerating ramp-up, safeguarding uptime, and maximizing your return on investment.

Why a Structured Installation Matters

The long-term efficiency of a packaging line design depends not only on the equipment selected but also on how precisely that equipment is installed, integrated, and commissioned.

OCME USA’s turnkey approach addresses every critical detail, from mechanical tolerances and clean cabling to validated software settings and early operator engagement. This level of precision minimizes costly rework, accelerates ramp-up, and ensures the line reaches its performance targets right from the start.

Phase-by-Phase Roadmap

A successful installation doesn’t happen by chance. The following roadmap outlines each phase of the packaging line design process.

Pre-Installation Planning

An OCME USA project manager hosts a multi-department kickoff, reviews existing conveyors and mezzanines, and delivers final layout files before any crate ships.

|

Key Task |

OCME USA Responsibility | Customer Responsibility |

|

Kick-Off Workshop |

Confirm objectives, speeds, and utilities |

Supply baseline production data |

| Layout Drawings | Issue 2D/3D plans |

Review and approve drawings promptly |

| Utilities Checklist | Specify air, power, drains, and network | Complete the necessary civil works |

|

Risk Assessment |

Verify machine guarding compliance with OSHA and CE standards | Review and sign off on safety recommendations |

Delivery, Unloading, and Staging

Equipment arrives in sequenced, clearly labeled loads by installation zone to minimize floor congestion. OCME USA technicians and the customer’s procurement team jointly verify packing lists and inspect each unit for potential transit damage before staging.

Mechanical Assembly

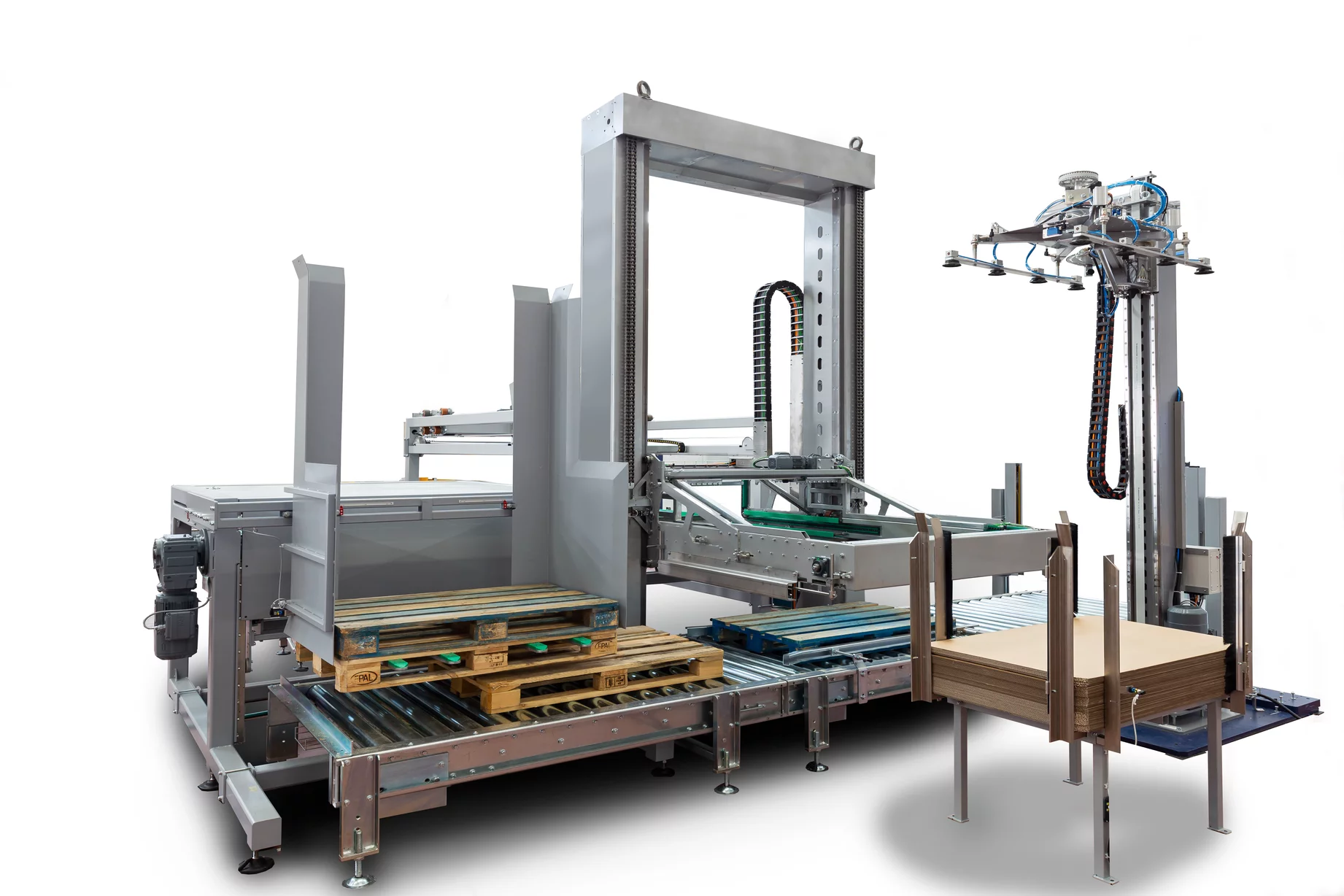

Equipment frames are leveled, anchored, and aligned using precision laser tools to ensure that fillers, case packers, palletizers, and Auriga Forklift LGVs share a unified datum. Conveyor systems, change parts, and guarding panels are installed next, followed by lubrication and dry rotation checks to validate mechanical readiness.

Electrical & Controls Integration

All power, I/O, and field-bus wiring is routed through color-coded trays for ease of maintenance and future upgrades. PLCs, drives, and HMIs are connected to the plant’s network infrastructure and tested against safety interlocks and system readiness requirements.

Software Configuration & Connectivity

Each machine is registered on OCME USA’s secure remote-maintenance server, enabling encrypted VPN access for diagnostics, only when customer-authorized. System data is also fed into customized dashboards for real-time overall equipment effectiveness (OEE) tracking. Supervisors receive login credentials for OCME USA’s customer portal to monitor spare parts orders, service tickets, and support history from any connected device.

Commissioning: FAT to SAT

Commissioning bridges the gap between factory testing and full production by validating system performance before shipment and on-site under real operating conditions.

Factory Acceptance Test (FAT): Conducted in Italy before shipment, the FAT verifies speed targets, format changeovers, and safety logic using customer samples.

Site Acceptance Test (SAT): Repeats the FAT protocol under live production conditions. Any fine-tuning requirements are logged, resolved, and cleared prior to final handover.

Performance Ramp-Up

An OCME USA commissioning engineer remains on-site for the first full production week. They monitor OEE, coach operators on optimal line operation, and assist with issue resolution — ensuring a smooth transition from installation to full-scale production.

Training & Knowledge Transfer

The OCME USA Training Academy equips your team with the skills to operate and maintain equipment confidently and independently. Training includes classroom instruction, hands-on machine sessions, and 24/7 access to a dedicated e-learning portal.

Courses are tailored for operators, maintenance personnel, and in-house trainers. Each concludes with a competency assessment and certification, enabling teams to resolve up to 80% of alarms without external assistance.

After-Sales Ecosystem

OCME USA’s service infrastructure is designed to protect your packaging line’s long-term performance and maximize uptime across every installation. Our customers benefit from a flexible, tiered support model tailored to their production needs.

On-Site Support

OCME USA maintains a nationwide network of field service engineers who specialize by machine family for faster fault identification and resolution. Services include diagnostic audits, emergency repairs, scheduled overhauls, and equipment upgrades — all performed with a deep understanding of your specific system configuration.

24/7 Remote Assistance

Customers have direct access to a multilingual support center capable of resolving issues via secure VPN or augmented-reality headset — no travel delay required. More than 900 machines are actively connected to this system, with support available through ticket bundles or fixed-fee annual contracts.

Genuine Spare-Parts Programs

Pre-assembled spare part kits keep critical belts, sensors, and drives on-site, minimizing downtime. OCME USA proactively flags components nearing phase-out and recommends retrofit packages to extend machine life.

Modular Warranty & Service Contracts

Customizable service plans combine preventive visits, rapid-response coverage, stocked spare parts, and optional extended warranties — all under a fixed, predictable fee structure. These contracts are available in three- to five-year terms, giving customers clear visibility into lifecycle costs and support expectations.

Integrated Equipment Highlights

OCME USA’s systems are engineered for seamless integration and optimized end-of-line performance. Each solution is designed to deliver speed, flexibility, and long-term efficiency, whether implemented individually or as part of a fully automated packaging line design.

- High-Speed Palletizing: OCME offers various palletizing solutions, including traditional, single-column, and robotic models that support layer or row forming.

- Versatile Shrink Film Packers: Designed for speed and adaptability, OCME’s shrink film packers handle up to 450 packs per minute. These systems can be paired with wrap-around modules for combination operation.

- Gemini HT Combi System: Integrates wrap-around case packing and shrink wrapping into a single machine frame. This space-saving solution reduces energy consumption and simplifies operations.

- Case-Packing Integration Guide: OCME provides a comprehensive case-packing integration guide that outlines best practices for equipment sequencing, operator training, and FAT/SAT protocols — all critical factors in maximizing ROI.

- LGV Performance Monitoring: Auriga LGV case studies demonstrate how remote performance tracking and predictive diagnostics improve OEE across multiple shifts and reduce the need for manual intervention.

Typical Timeline Checklist

|

Week(s) |

Milestone | Details |

| Weeks 0 to 4 |

Kick-Off & Drawings |

Layout issued for customer approval; utilities confirmed and baseline data reviewed. |

|

Weeks 5 to 8 |

Civil & Utility Works | Site preparation completed, including pits, anchors, and power/network drops. |

|

Weeks 9 to 12 |

Equipment Shipment | Crates arrive and are staged by line zone to streamline installation flow. |

|

Weeks 13 to 17 |

Mechanical & Electrical Installation | OCME USA crew on-site; plant provides forklifts, access, and safety escorts. |

|

Week 18 |

Dry Tests | Mechanical alignment and rotation tests performed; sample product supplied. |

|

Week 19 |

SAT & Training | Site Acceptance Test executed; staff completes certification and handoff training. |

|

Week 20+ |

Ramp-Up | OCME USA engineer monitors line performance, fine-tunes settings, and supports OEE optimization. |

Five Steps for a Smooth Installation

Successful installations rely as much on preparation as they do on equipment quality. These steps help ensure a smooth, efficient launch and long-term line performance.

Approve layout drawings early to confirm utilities and prevent last-minute civil work revisions.

Assign a cross-functional team to streamline decisions across engineering, quality, and IT.

Budget for training and spare parts in advance so operators are equipped and confident from Day One.

Use remote support tools to accelerate troubleshooting across multi-shift operations.

Consider a service contract to stabilize maintenance costs and secure guaranteed response times.

An OCME USA installation is more than just placing machines — it’s the integration of engineering precision, digital connectivity, and long-term partnership. From the first layout drawing to the tenth year of production, OCME USA remains your single, accountable partner in secondary packaging and logistics performance.

Ready to begin? Contact OCME USA today to discuss your installation project timeline and explore tailored support options.