In industrial packaging, case packing and carton packing both refer to secondary packaging processes, but they differ in how containers are formed and loaded. Case packing typically means placing products into pre‑made corrugated boxes (cases) for shipping, whereas carton packing often involves forming or erecting cartons around the products themselves (sometimes called cartoning). For example, OCME’s wrap‑around case packers take flat cardboard blanks and fold them tightly around grouped products, sealing them into a box. In contrast, pick‑and‑place case packers load products into already‑erected cases or trays. Understanding these differences helps manufacturers choose the right method: carton‑based systems are ideal when you can feed blanks and need very high speeds or special carton styles, while traditional case packers suit situations with pre‑made cases or more delicate products.

How Each Method Works

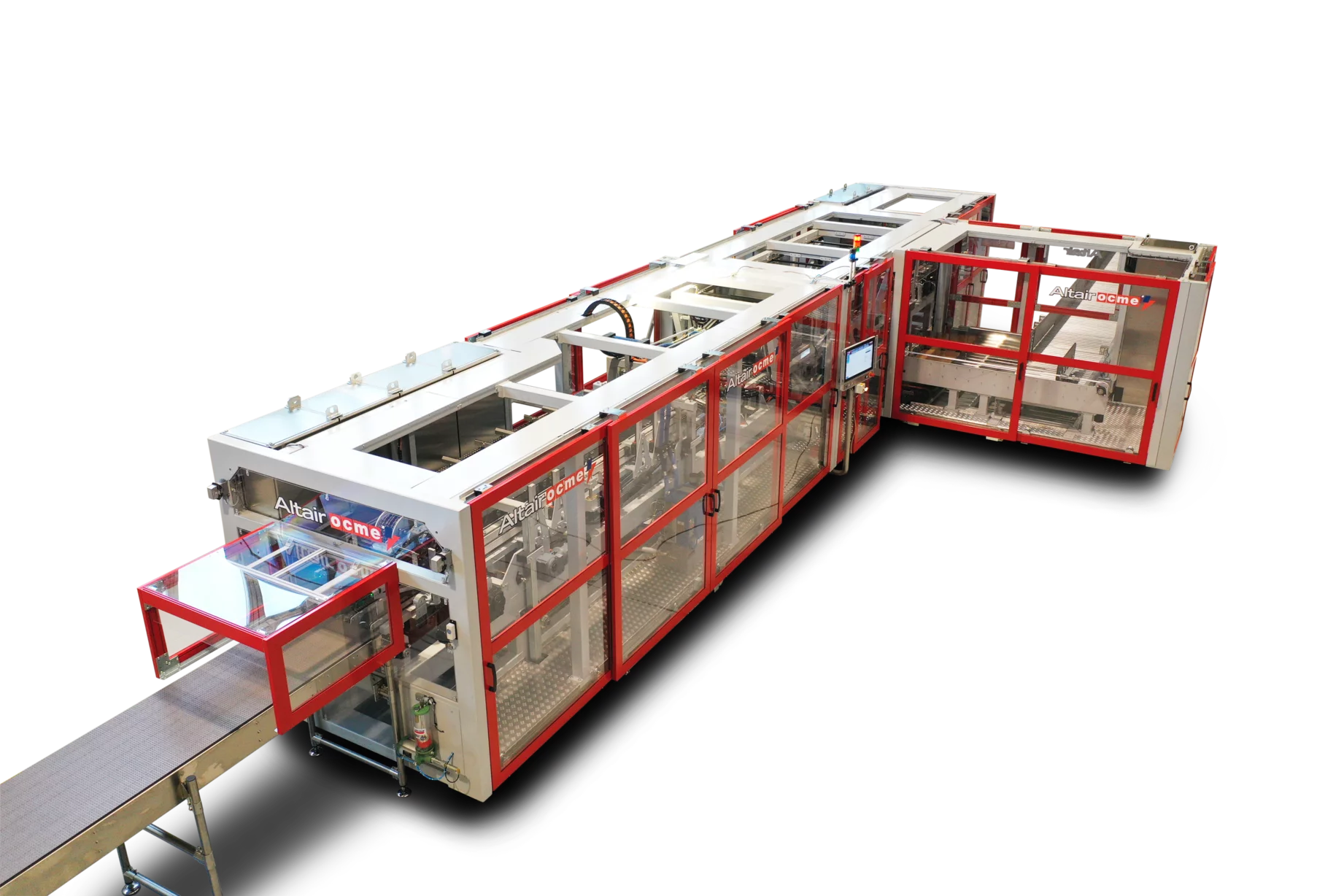

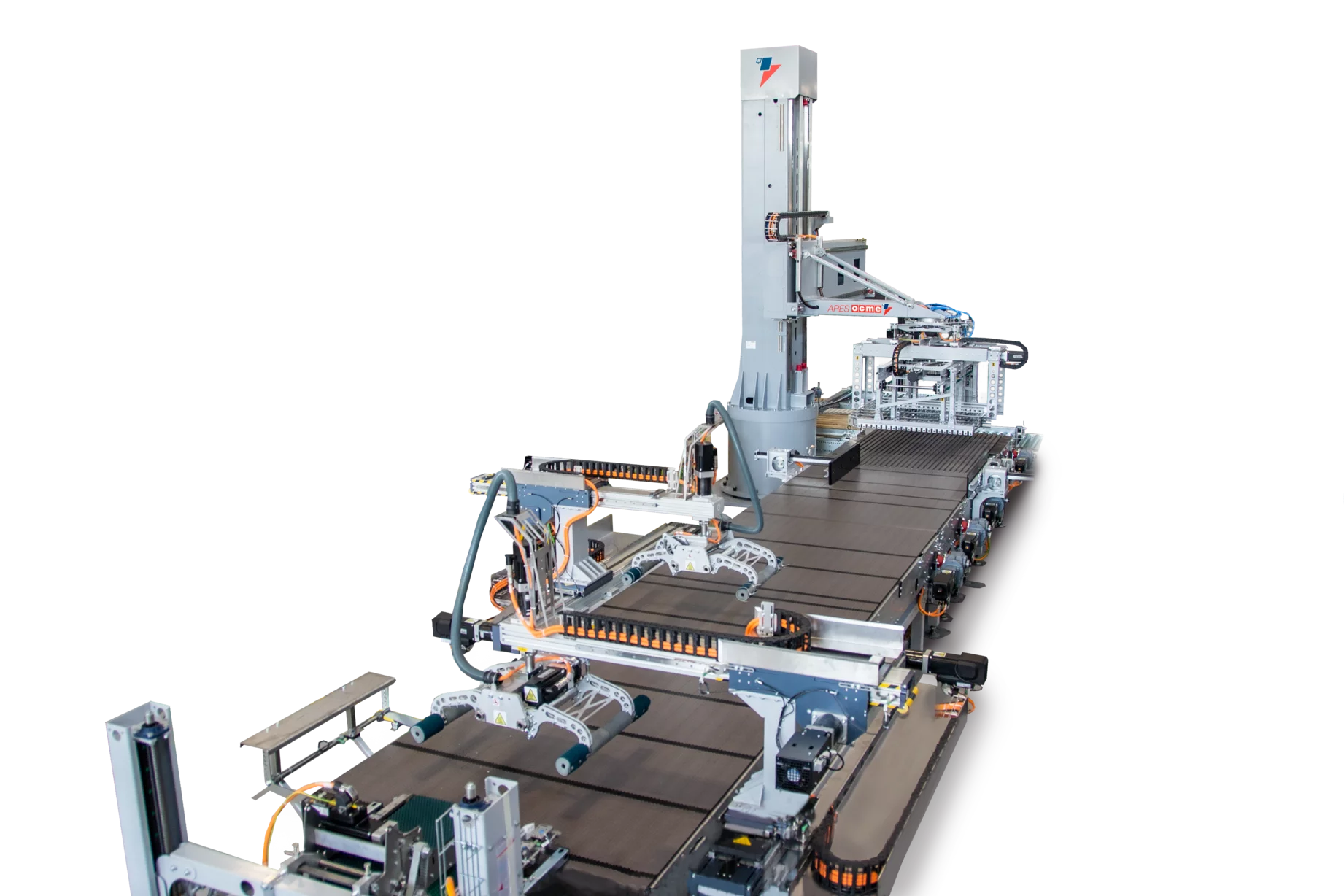

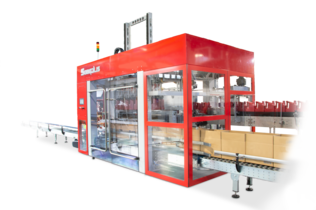

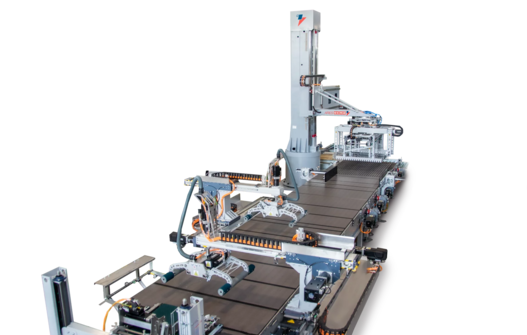

Case packing machines load items into preformed cases. There are two main approaches: pick‑and‑place and shrink/stable grouping. Pick‑and‑place case packers (e.g., OCME’s Scorpius or Leo models) use robotic arms or precise mechanisms to insert products into cases. This method handles delicate, irregularly shaped, or glass products gently, adapting to various configurations. OCME pick‑and‑place machines can run up to about 40 cartons per minute, ensuring secure placement and high‑quality packing. By contrast, wrap‑around case packers use a flat blank to form the case around the product in one motion. OCME’s Altair series is an example: it wraps a corrugated carton blank around bottles or containers and glues it closed. Wrap‑around packers are faster (Altair HT can reach 100 cartons per minute) and produce tight, compact cartons. In both cases, the result is a robust corrugated box ready for shipping or retail display.

Carton packing (or cartoning) often refers to packaging individual items in smaller retail cartons or trays. Vertical or horizontal cartoners (not core to OCME’s line) would feed cartons and insert products. However, OCME’s offerings blur the line: their wrap‑around systems essentially act as high‑speed cartoners by forming cartons in‑line. For very high throughput, OCME also provides combined machines (e.g. the Gemini HT), which integrate wrap‑around carton packing with shrink‑wrapping forming and sealing cartons around products, then applying a film over the packed cases for extra stability. In summary, wrap‑around (“cartoning”) machines eliminate separate case erection, while pick‑and‑place case packers and pre‑made cases are better when product handling or carton variety is needed.

When to Use Each Method

The choice depends on the product and line requirements. Wrap‑around cartoning is best for high‑speed lines and uniform products where you can supply stacks of flat blanks. It maximizes speed and carton strength Altair wrap‑around packers deliver very compact cartons at up to 100 cpm. Industries like beverage or edible oil often use wrap‑around packers since bottles run in lanes, and speed is critical. For example, OCME’s beverage industry solutions rely on these systems for secondary packaging. Pick‑and‑place case packing is more flexible and gentle, suitable for fragile items or when you need to mix different product shapes. It runs at moderate speeds (up to ~40 cpm) but can handle odd shapes, inserted trays or partitions, and smaller production runs more easily. Food, home‑care, and consumer‑goods manufacturers often use pick‑and‑place packers when variations in products or pack styles are common. Additionally, if the packaging needs a shelf‑ready display or unusual carton styles, a cartoning machine or wrap‑around packer (which can create special easy‑open cartons or trays) may be chosen.

In general:

• Use wrap‑around/cartoning when you have uniform products, need maximum speed, and can feed blanks. OCME’s Altair HT and Gemini HT models excel here, forming cartons in‑line at high speed.

• Use pick‑and‑place case packing when products are delicate, cartons come pre‑erected, or formats change often. OCME’s Scorpius and Leo pick‑and‑place packers handle a variety of containers up to 40 cases per minute.

• Consider hybrid/combo systems when you want both: for example, OCME’s Combi machines that combine wrap‑around cartoning with film wrapping.

OCME Machinery for Each Method

OCME USA provides a full range of end‑of‑line equipment for both approaches:

• Wrap‑Around Carton Packers: The Altair series (including Altair HT) is OCME’s flagship for high‑speed wrap‑around packing. These machines form cartons from blanks, insert products, and hot‑melt glue them shut. They can also insert partitions or trays if needed. Altair HT is capable of 100 cartons/minute, making it ideal for very fast lines. The Gemini HT is a combined system that adds an integrated shrink‑wrapper to the wrap‑around packer (in case shrink film is also required).

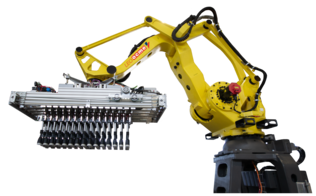

• Pick‑and‑Place Case Packers: OCME’s pick‑and‑place machines (described on the Case Packers & Cartoning Machines page and in the Pick & Place Case Packers section) use robotic or precision pickers to load cases or trays. These are tailored for versatility and gentle handling. For example, the Scorpius cartoning machine and Leo crater/decrater can flexibly pack irregular bottles, jars, or non‑standard packs. OCME pick‑and‑place packers achieve up to 40 cases per minute while adapting to many container types.

• Shrink & Stretch Film Packers: Although not strictly “case” or “carton” packers, OCME also offers shrink/tray wrappers (film packaging) that can bundle products prior to secondary packing and integrate seamlessly with wrap‑around or pick‑and‑place lines.

• Carton Formers (Case Erectors): In lines using pre‑formed cases, OCME includes automatic case erectors that fold flat blanks into sturdy boxes before the packing stage.

• Palletizing Systems: After carton or case packing, OCME’s palletizers & depalletizers stack finished cartons onto pallets. OCME offers traditional layer palletizers, robotic palletizers, and hybrid systems, ensuring that case‑packed or wrap‑around‑packed products are efficiently palletized for warehouse shipping.

The combination of these machines enables OCME customers in the beverage, food, and home/personal‑care sectors to build turnkey lines that cover everything from filling to case/carton packing to palletizing. For instance, OCME’s engineers often customize layouts where a case erector feeds a pick‑and‑place case packer for fragile glass bottles, or where a wrap‑around packer immediately follows a filler/labeler for PET bottles. According to OCME’s product information, their case packers handle “a wide array of configurations, including wrap‑around, pick‑and‑place, and tray packing” at rates from about 10 to 100 cartons per minute. This underscores the breadth of solutions available.

Choosing the Right Method

In summary, if your operation needs high throughput and can standardize on a carton style, wrap‑around carton packers such as Altair HT offer unbeatable speed and a tight, compact carton. If you need flexibility for different product shapes or gentler handling, pick‑and‑place case packers are more appropriate, even if slightly slower. OCME’s experts can advise on hybrid solutions too for example, combining a case packer with a shrink‑wrapper (as in Gemini HT) or adding partitions and trays.

Ultimately, the goal is seamless automation: products exit the filler/labeler, get grouped and packed into cartons or cases by OCME machinery, and then move on to stretch‑wrapping or palletizing systems for final handling. OCME’s fully integrated lines ensure minimal downtime and ease of changeover, while the company’s in‑house support helps maintain long‑term performance. To explore how OCME can optimize your secondary packaging, visit the Case Packers & Cartoning Machines hub or contact the OCME USA team for a custom line assessment.